I have been visiting r/sovol quite often since I bought my Sovol SV06. It is a lot off fun to see how other people are getting along with their printers!

There is a lot of advice over there. I am disappointed to see that a lot of the advice has gone from “it might be a good idea to…” to “you definitely better…” over the last few weeks.

It isn’t just about disassembling brand-new printers in order to pack the bearings with grease. There are people implying that you’re not going to be able to get a good first layer if you don’t do the silicone mod to your bed. There also seem to be a lot of people that think that you won’t get decent prints if your Z-axis motors aren’t absolutely perpendicular to the Y-axis.

Yes. It would be better if the bearings were greased, and it would be even better if they were greased from the factory. Yes. It would be better if the print bed was perfectly flat. Yes. It would be better if the printer was more square.

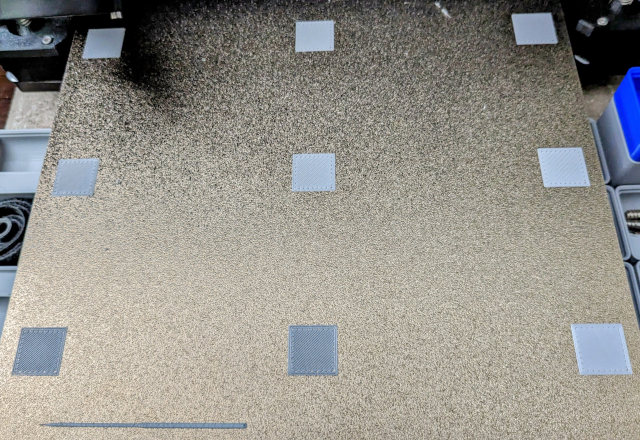

My bed isn’t flat. My bearings aren’t greased. My Z-axis is off by up to 1.5 degrees. My printer is printing just fine.

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

- The Sovol Comgrow T300 Only LOOKS Like a Bambu A1

- Marlin Input Shaping, My Sovol SV06, and My Twenty-Minute Benchy

- The Sovol SV07 and Rethinking My Dislike of V-Wheel 3D Printers

- My Sovol SV06 — Two Months Later

- My Sovol SV06 – Can It Match My Prusa MK3S?

- I Bought a Sovol SV06 3D Printer

- Sovol SV06 at Sovol.com

Why you shouldn’t immediately disassemble your printer

I am just taking a guess, but I suspect that this is your first 3D printer and that you are new to 3D printing. Please don’t take apart your Sovol SV06 until you get some good prints out of it.

When you take apart all three axes, load the bearings full of grease, then reassemble the printer you are introducing all sorts of new potential problems.

You have bought one of the most inexpensive Prusa MK3 imitations, and Sovol is for sure cutting corners and using the cheapest components they can acquire. I don’t know what the odds look like, but I wouldn’t that at least 5% of us have received a printer with at least one bad component.

Did you break something while taking the printer apart? Or did it come from the factory that way? You should wait to see how the machine works before taking it apart.

I will not be greasing my bearings

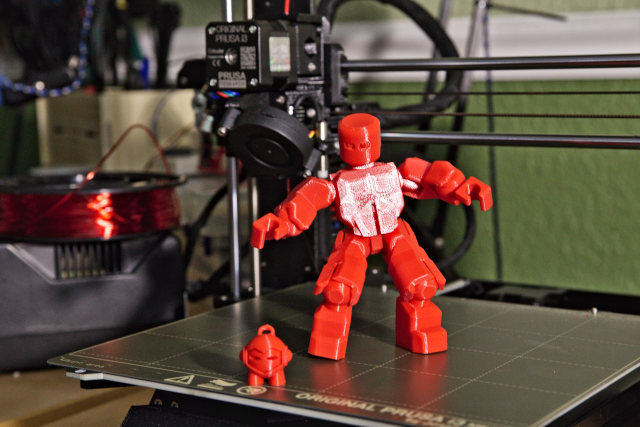

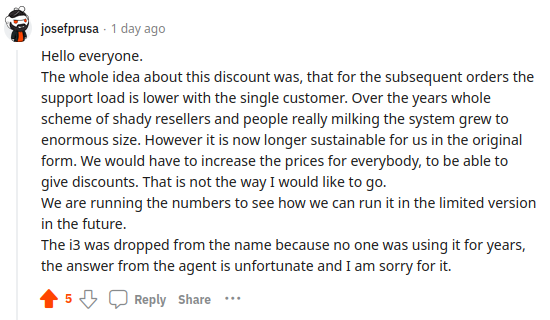

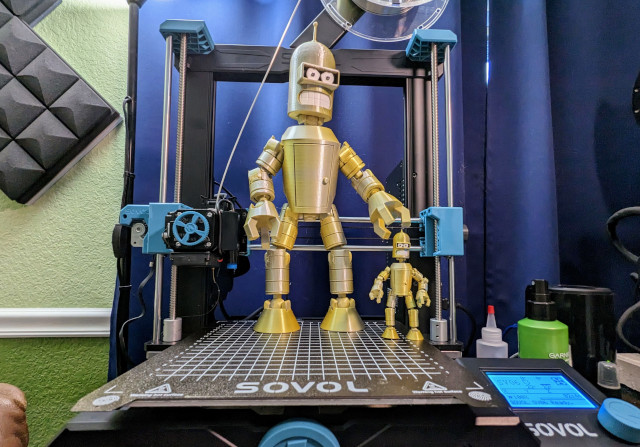

I am also not running my bearings completely dry. I saw a recommendation on r/sovol that suggested putting PTFE lube on the linear rods. I have a big bottle of PTFE lube for bike chains in the garage. It took me 20 seconds to squeeze a few drops onto all the rods while my oversized Mini 13 Bender was printing.

Linear rods and bearings are cheap, and even completely ungreased, there is a good chance that I will never run my Sovol SV06 for enough hours to put significant wear on the rods. I don’t want to put time into fixing something so inexpensive that probably won’t even wear out anyway.

The folks posting on r/prusa3d were making a big deal about Prusa not properly packing the bearings with grease on the preassembled Prusa MK3S right around the time I bought mine. It has been printing for almost three years. I have put somewhere between 15 and 20 kilograms of filament through my Prusa MK3S. All the rods feel brand new, and I have done absolutely nothing to lubricate them in any way.

My bed is probably warped, and my Z-axis is for sure out of alignment

My first 3D printed needed a perfectly flat piece of glass to print on, and that piece of glass had to be perfectly trammed. Then the Prusa MK3 came along, and I never had to worry about that again. Mesh bed leveling can correct for A LOT of imperfection in the bed and a pretty high degree of slop in rest of the printer.

The Sovol SV06 is a 3D printer. It isn’t a CNC mill. It isn’t even a CNC router. There’s quite a bit of error even just in the amount of plastic that may or may not be extruded as the tool is moving around. For most of us, a slightly out of alignment Z-axis isn’t going to make a difference that we are going to notice.

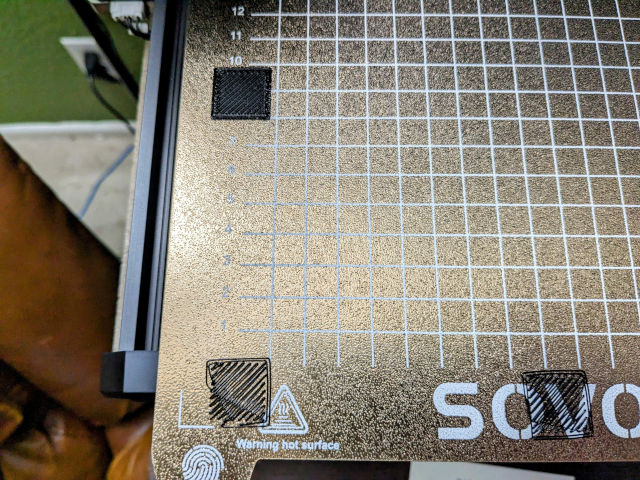

NOTE: I didn’t take any good photos of the ABS spool holder. I only have this quick snapshot that I took when I was surprised how cleanly the completely unsupported overhang managed to print.

I don’t think I have printed anything much taller than four or five inches on the Sovol so far. Bender’s torso is a bit over three inches, and it doesn’t appear out of whack. I printed a second spool holder in ABS that is a little over four inches tall. It looks fine.

My Sovol SV06 was refurbished. Do you know why it was returned to Sovol?

We have no way to know for sure why the original owner returned his Sovol SV06, but I have a well educated guess!

I had a good bit of trouble getting the filament to load. By a good bit of trouble, I mean it took me about three tries and about two minutes. There was some white filament already in the extruder.

The previous owner couldn’t have cut the filament off deep inside the extruder like this. I would bet that something went wrong, and then they couldn’t load filament again. They couldn’t figure it out, so they shipped the printer back.

I don’t know how common this is today, but it used to be extremely common when I ran the 3D printing lab at our local makerspace. People would run into trouble, tell me that they spent 20 minutes trying to figure out why they couldn’t load filament in the printer, and they would ask for help.

More often than not, there was no problem. I was usually able to load filament without a problem.

- Refurbished Sovol SV06 at Sovol.com

If you really want to grease your bearings or straighten your frame, I think that you should!

I don’t want you to not maintain your printer. I just want you to think before you start unscrewing things.

So many problems that get posted in r/sovol are just people who haven’t learned to properly calibrate their z-offset for their first layer. Half of the time they explain all sorts of convoluted steps they have taken to correct the problem.

Ask for help. Make sure you try the easy fixes before you decide that your problem is one of the difficult ones. A good troubleshooter knows to eliminate problems that are easy to test for first. Ordering hose to do the silicone bed mod won’t help you if you problem is that you are printing 0.15 mm too far from the PEI sheet.

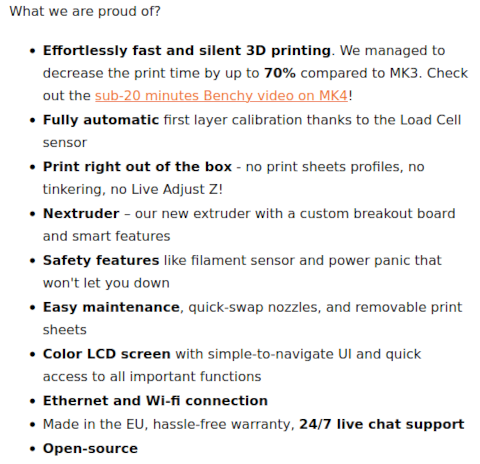

Sometimes the printer is the hobby

My 3D printers are here to support my other hobbies. I don’t want to assemble my own Prusa MK4 kit. I don’t want to take apart my printer to grease the bearings. I just want them to keep on working with as little effort invested as possible.

I know a lot of folks who feel differently about this. The 3D printer itself is their hobby, and maybe it is your hobby, too!

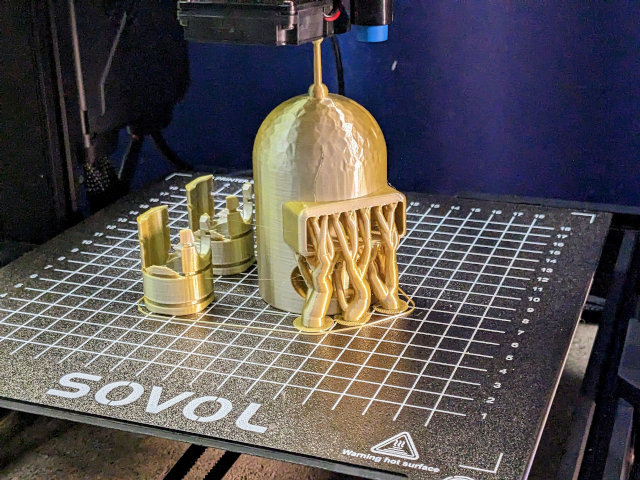

If it is, go ahead and grease those bearings. Square up your Z-axis. Print upgraded parts! Go have fun!

Please just make sure your brand new printer works before you take it apart. You’ll have a much better time talking to Sovol’s very limited customer service department if you don’t have to explain that you didn’t break anything while greasing the bearings.

We paid $250 for a printer that Prusa charges $1,111.31

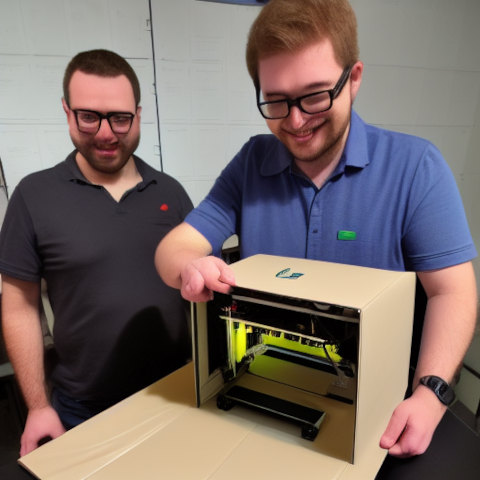

Sort of. I paid $1,111.31 for my fully assembled Prusa MK3S after shipping and taxes. I paid $169 for my refurbished Sovol SV06. The Sovol wasn’t fully assembled, but it is in way fewer pieces than a Prusa MK3 kit, so I am going to stick to comparing the Sovol to the ready-to-go Prusa.

Sovol cuts a lot of corners to get the price this low. Sure, they are made in China, so the labor prices are lower, but many of the parts on the Prusa are also made in China. That only accounts for some of the difference.

Prusa responds to support requests in a timely manner. Reddit makes me think Sovol is bad at this. Prusa ships replacement parts quickly. Reddit makes me think Sovol is bad at this. Prusa uses power supplies that don’t immediately fail, and they ship control boards that don’t fry when you plug them into a USB port.

Those last two make me think Sovol does a pretty bad job at quality control. We are for sure taking a gamble when we buy from Sovol. We are doing better than flipping a coin, but it sure feels like we are rolling the dice. At least it seems like we are rolling a 20-sided die instead of a 6-sided die.

Just hope you don’t roll a one!

Conclusion

I like the Sovol SV06 a lot. The SV06 and SV06 Plus are my favorite printers under $750. I think you should buy one. They are both packed full of rather premium features at a more than reasonable price.

You just have to understand what you are buying, and who you are buying it from. Sovol has executed a lot of things well here. They have nice injection-molded parts and a rather impressive and inexpensive to replace extruder assembly, but many of the components are as cheap as they can get away with, and they have poor customer service.

Are you planning on buying a Sovol SV06, or do you already own one? How was your experience out of the box? Is your frame as out of alignment a mine? Are you still getting good prints anyway? I want to hear about your experiences in the comments, or stop by the Butter, What?! Discord server to chat about it!

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

- Marlin Input Shaping, My Sovol SV06, and My Twenty-Minute Benchy

- The Sovol Comgrow T300 Only LOOKS Like a Bambu A1

- The Sovol SV07 and Rethinking My Dislike of V-Wheel 3D Printers

- My Sovol SV06 — Two Months Later

- My Sovol SV06 – Can It Match My Prusa MK3S?

- I Bought a Sovol SV06 3D Printer

- Sovol SV06 Plus at Sovol.com

- Sovol SV06 at Sovol.com

- Sovol SV06/SV06 plus double filament/spool holder at Printables