Earlier this month, I wrote about ordering myself a Bambu A1 Mini 3D Printer. I could rehash all the reasons why I chose to add an A1 Mini to my collections instead of a Bambu P1S, or why I think the A1 Mini is a good size, but I feel like we will indirectly cover that sort of stuff while we talk about how fantastic the printer has been so far. Let’s summarize some of what I have already learned.

The Bambu A1 Mini is a little slower than my souped-up Sovol SV06; sometimes by a big margin, but usually only by a little. The Bambu dials in a perfect first layer and flow rate every time, so the prints all come out cleaner than my Sovol.

I can’t decide whether I am disappointed or relieved that the A1 Mini didn’t immediately make my Sovol SV06 obsolete. Maybe we will figure that out together!

The A1 Mini is tiny. I wasn’t sure if the A1 Mini sitting next to the AMS Lite seemed to take up more space or less space than I expected, so I got out the tape measure. The combo is about 23” wide and 17” deep. I think that is interesting, because that is precisely the footprint my Sovol SV06 requires, except the Sovol is 17” wide and 23” deep!

- The Bambu A1 Mini – The Best Choice for Your First 3D Printer

- I Bought a Bambu A1 Mini Even Though I Know What I Am Doing

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

- Marlin Input Shaping on the Sovol SV06: Three Months Later

- The Sovol SV06 – Is It Still Worth Buying in 2024?

- The Sovol Comgrow T300 Only LOOKS Like a Bambu A1

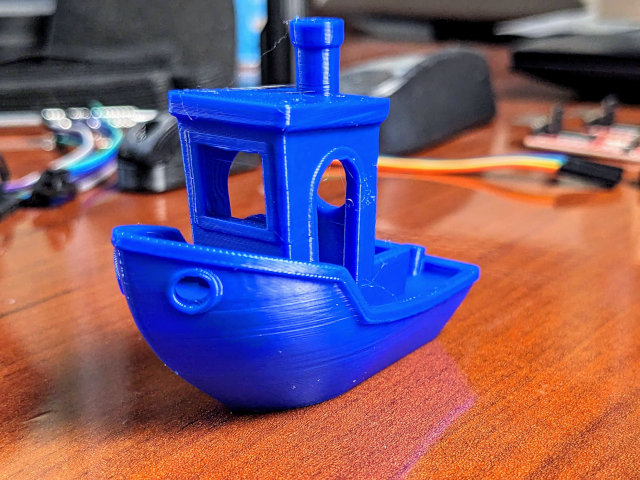

My first Benchy

The A1 Mini ships with a sliced SpeedBoatRace Benchy already on the printer. I didn’t print that. That file is specially tweaked to print super fast. I wanted a realistic test, so I sliced my own Benchy with the 0.16-mm profile. It took a little over 40 minutes to print, so my Sovol SV06’s 21-minute Benchy printed in half the time. I even used the same filament just to be fair.

These Benchy’s are apples and oranges. My Sovol SV06’s Benchy breaks the SpeedBoatRace rules by using 0.24-mm layers, and those thick layers are noticeable in the final product. Bambu definitely dials in the first layer better than I ever did on the Sovol, and almost every fine detail of the Benchy came out better on the A1 Mini.

The hull came out cleaner on the Sovol, but to be completely fair here, the clean Benchy on my Sovol had a huge external fan blowing across the printer.

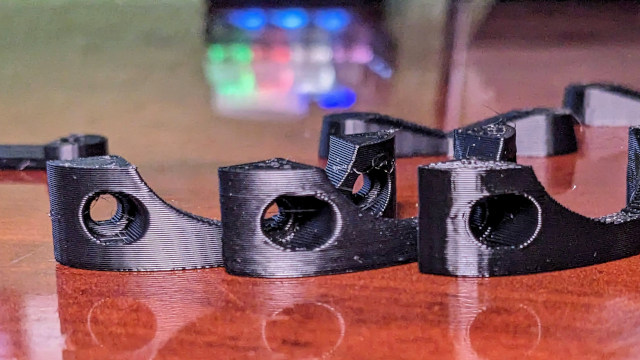

Testing PETG support interface with the AMS Lite

I expect having the option to print in four colors will be fun, but that isn’t the reason why I was excited about buying the A1 Mini Combo. I keep hearing and seeing that PETG supports don’t stick well to PLA, so you can pop the supports right off! And you only have to print the interface layers in PETG, so the printer doesn’t have to change filament for every single layer of the support structure. Isn’t that neat?!

I didn’t have a handy part to test. I wound up printing one of the camera adapter plates for my no-sew backpack hooks. The part is designed to print without supports, so I just flipped it so the wrong side was up, and I made some tweaks to the slicer settings to use PETG for the supports.

NOTE: Believe it or not, that is the smoothest surface of the print as far as my finger can tell! If I used black PLA with black PETG, I don’t think we’d ever know there was support material in that hole!

I was surprised how many clicks it took to set this up well in OrcaSlicer. I had to pick the material, change the number of interface layers, change the interface layer distance to zero, and increase the density of the interface layer. I kind of expected there to be a single button to hit to make all this happen!

I wanted to make sure it would be easy to see what was going on, so I used white PLA for the part and black PETG for the supports. This was probably the worse possible combination, because you can see lots of leftover bits of black PETG on my PLA part.

The supports didn’t completely pull away quite as cleanly as I was led to believe, but most of it did pop out easily and cleanly. I just had to clean up one extra layer of PETG.

Even though the layer looks behind rough due to the black bits, the bottom of the supported part of the print feels smoother than the top of the print. It is quite impressive!

I suspect that I could have gotten an easier separation here if I changed the pattern of the interface layer. I am sure I will be experimenting with this more in the future.

- Marlin Input Shaping, My Sovol SV06, and My Twenty-Minute Benchy

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

I had to try printing ABS

And it worked really well! OrcaSlicer was being a pain about letting me add an ABS filament profile, so I just copied a PETG profile and adjusted the temperature a bit.

I don’t print large parts using ABS. I print small structural parts, and they are usually parts that I need to survive in the sun here in Texas. Small parts print perfectly well on my Prusa MK3S and my Sovol SV06, but I was worried that the Bambu A1 Mini’s bed-temperature limit of 80C would be too low.

Left to right: ABS on my A1 Mini, ABS on my Sovol SV06, PETG on my A1 Mini.

I printed a set of my no-sew backpack pieces. I kept an eye on things just in case something came loose from the bed during the print, but I learned afterwards that if anything, the ABS adhered too well to the textured PEI sheet.

I don’t expect to have any problems printing batches of these parts on the A1 Mini.

UPDATE: My test prints with ABS were with three or four small parts. My next print had about twice as may parts, and one of them had about three times the footprint of the others. The big part came loose on me during the print. Your mileage may vary if you try to print ABS, because so far, my own mileage is definitely varying!

- The Bambu A1 Mini – The Best Choice for Your First 3D Printer

- I Bought a Bambu A1 Mini Even Though I Know What I Am Doing

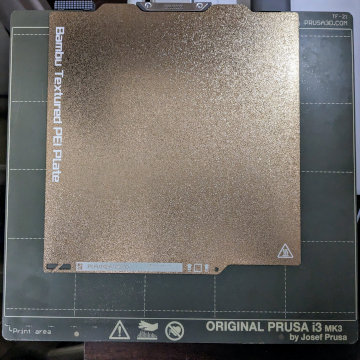

Is that 180x180 bed too small?!

I had a slightly worrisome moment while unboxing the new printer. The textured PEI sheet is right on top of everything along with the quick-start guide. I was out in our cavernous living room when I was unpacking everything, and I have to say that the print surface looked absolutely minuscule out there!

Once I got it into my office, though, it looked like a much more reasonable size. Yes. It is much smaller than the Prusa MK3 or the Sovol SV06, but the Bambu A1 Mini has quite a reasonable print volume.

If you want to be able to print a Scout Trooper helmet, then the A1 Mini isn’t the right printer for you. For that matter, neither are the Prusa MK3S, Prusa MK4, or the Sovol SV06. You need something at least as big as the Bambu P1S or the Sovol SV06 Plus!

This tiny printer will be fine for nearly everything I print. You can tell by the wear on the grid printed on my Sovol SV06 that I mostly only use a 2” square in the center of the bed.

I mostly send one or two small parts to the printer for testing, and they rarely take more than 20 minutes to print. Then I check that the parts will fit, make any necessary tweaks, and send another small 20-minute job to the printer. Then I repeat that until I get it right.

If you work like I do, you will be fine.

Should you buy a Sovol SV06 or Bambu A1 Mini?!

An answer to this question will need to be a whole blog post on its own, but I had some good thoughts long before the printer arrived, and most of them have already been confirmed in the first day of ownership. It seems worth writing a few paragraphs here.

These printers are not directly comparable. The small, fast, much more user-friendly machine costs $100 more, and Bambu has much better quality control than Sovol. The bigger, still capable machine costs $100 less, but Sovol has pretty poor customer service.

The Sovol SV06 is $195 now. The design and technology is very comparable to the Prusa MK3S, and that design is a proven workhorse. If you get a good machine from Sovol, it ought to be a tank, and you’ll have no trouble finding parts to repair it. The bummer is that this is outdated tech that was extremely exciting in 2016.

The Bambu A1 Mini is modern and friendly, but it costs $299. You don’t have to learn how to calibrate your own z-offset. You don’t have to learn to dial in your flow rate for your filament. These are the two most common problems over on /r/FixMyPrint, and Bambu does it for you. You also get a camera, WiFi printing, and remote print monitoring.

You are paying an extra $104 to save yourself hours of potential aggravation, to receive a more modern and higher quality product, and for a much faster printer that you can send prints to from your phone or computer. The Bambu may be smaller, but you get a lot for the extra money.

If you want to try 3D printing for the first time, I feel like the Bambu A1 Mini is one of the best options.

But you said your Sovol SV06 is faster than your Bambu A1 Mini!

So far, this does seem to be true. The trouble is that I put in a lot of work to get it to that point.

If I paid myself minimum wage, I don’t believe it would have cost me the entire $104 to get the Sovol to where it is today, but I’ve been upgrading and configuring Marlin on 3D printers for eight years. I suspect it will take you longer, and I hope both of us value our time more than that.

If you think it will be fun, then by all means, grab a Sovol SV06 or SV06 Plus and have fun! Just remember, the performance isn’t the only difference.

- Marlin Input Shaping on the Sovol SV06: Three Months Later

- The Sovol SV06 – Is It Still Worth Buying in 2024?

What’s next?

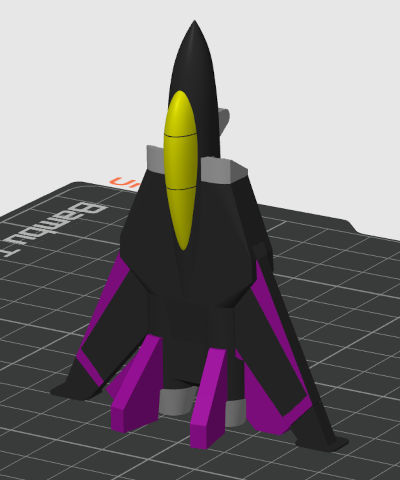

I need to do a legit and ridiculous multicolor print. I poked through my filament collection, and I decided to paint agepbiz’s awesome print-in-place F14 to look like Skywarp from The Transformers. I have black for the body, purple silk for some highlights, gray for the scoops, and coextrusion gold and silver to use for the canopy. I think it’ll be fun, but it will be a 12-hour print and take 20 times more filament than just printing a single-color jet, so I am going to put that off for at least a few days!

I want to see how well the A1 Mini switches to the next spool when a spool runs dry. I have quite a few nearly depleted spools. I figure I can drop a whole mess of Gridfinity bins on the plate to eat through those leftovers to see how well it does!

Other than that, it will mostly just be printing as usual. Except on a different printer!

What do you think? Is the Bambu A1 Mini at $299 cheap enough to be an impulse purchase? Is it worth paying the extra $100 and compromising on size for the modern conveniences and high speeds out of the box? Do you think I am correct when I say that everyone should have Bambu’s first-layer compensation and flow rate tuning on their first printer, or do you think new people should struggle to figure out how to set a z-offset? Let me know what you think in the comments, or stop by the Butter, What?! Discord server to chat with me about it!

- The Bambu A1 Mini – The Best Choice for Your First 3D Printer

- I Bought a Bambu A1 Mini Even Though I Know What I Am Doing

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

- My journey to a new 3D Printer: the Bambu Lab X1-Carbon at Brian’s Blog

- Marlin Input Shaping on the Sovol SV06: Three Months Later

- The Sovol SV06 – Is It Still Worth Buying in 2024?

- The Sovol Comgrow T300 Only LOOKS Like a Bambu A1