I am excited about the Sovol Comgrow T300. I don’t think I would ever pay $550 for this printer, but its print volume is at least 44 mm bigger in every direction. If the T300 lives up to its spec sheet, then it is probably an amazing printer if you actually really do need that extra print volume.

The T300 is obviously designed to make you think it is every bit as amazing as the Bambu A1 or A1 Mini. It isn’t even close. Almost all of the magic that makes the A1 an amazing printer is in the toolhead: fully automatic strain-sensor bed leveling, automatic filament flow control, air-printing and tangle detection, and 30-second nozzle swaps.

Much of the rest of what makes Bambu’s printers so awesome is their attention to detail in your printing workflow. They have meticulously tuned slicing profiles. Bambu printers will give you fast, beautiful prints out of the box with zero effort. We haven’t seen anything remotely close from Sovol yet.

- I Am Tentatively Excited About The Sovol SV08

- Marlin Input Shaping on the Sovol SV06: Three Months Later

- The Bambu A1 Mini – The Best Choice for Your First 3D Printer

- Sovol Comgrow T300 at Sovol.com

Real linear rails aren’t what make the Bambu A1 an amazing printer

The linear rails are a nice upgrade, and they sure do make the Comgrow T300 superficially resemble a Bambu A1, but those rails aren’t the upgrade that made the Bambu A1 so awesome.

The T300 is using an induction bed-leveling probe. Don’t get me wrong. These work great. They were the most exciting thing that the Prusa MK2 brought to the table in 2016. The trouble is that they require you to be knowledgeable, and they require manual tuning from time to time.

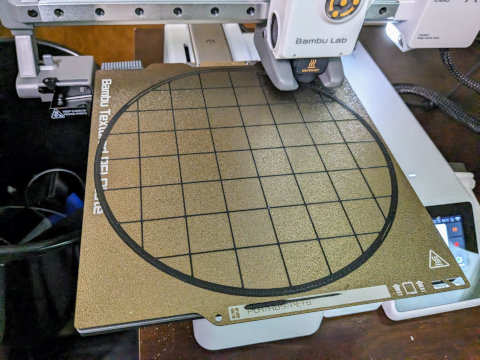

I paid for the whole build plate, so I am using the whole build plate!

I haven’t used my Sovol SV06 much since my Bambu A1 Mini arrived in December. I needed to use it last week, because I had to print something that wouldn’t fit on my A1 Mini. I had adhesion issues on the SV06 because my z-offset wasn’t quite right. I wasted about 15 minutes canceling the print, cleaning the build plate, and dialing in the z-offset.

All the Bambu printers detect the height of the print surface by physically touching it with the tip of the nozzle. It doesn’t matter if the weather changes, the bed expands due to heat, or if you swap in a thicker or thinner PEI sheet. A Bambu printer will give you a perfect first layer almost every time with zero effort on your part.

If you are new, this saves a ton of time and frustration. If you already have years of 3D-printing experience, then this just becomes one less thing to ever have to think about.

You shouldn’t be looking at the Comgrow Sovol T300. You should be shopping for a Bambu A1 or A1 Mini.

30-seconds to heat up?!

Alright. I’ve said enough bad things about the Comgrow T300. Lets talk about the good things.

It takes my Sovol SV06 two and a half minutes to go from clicking the upload and print button to actually starting to print my part. My Bambu A1 Mini takes almost six minutes to do the same thing. My tuned-up super-fast Sovol SV06 can give my Bambu a run for its money, so the Sovol can win these races when I am printing single small parts with this three-minute head start.

If the Sovol Comgrow T300 can heat the bed in 30 seconds, that would be a fantastic upgrade in certain situations! This makes no difference when you are printing a 48-hour Mandalorian helmet, but I sometimes spend a lot of time prototyping.

I might print a small part, see if the curves and dimensions match up correctly with something in the real world, make a few tweaks to the model, then hit print again. I might have to do this a dozen times.

Shaving four minutes or even two minutes off the print time could be the difference between printing a job taking 40 minutes instead of an hour. That might mean I could start and finish a project before meeting a friend for lunch instead of putting it off until next week.

This is extremely niche. Most of the time I don’t even care that the A1 Mini takes six minutes to start a print. It does a lot of work during those six minutes that the Sovol isn’t capable of doing. The A1 primes and wipes the nozzle, scrapes the nozzle super clean over the silicon brush, performs a vibration compensation process, and loads the color I selected from the AMS Lite.

Some of these things help ensure that my part is going to print successfully.

This is a cool feature of the new Sovol printer, but I would only be excited about it three days each year.

- Marlin Input Shaping on the Sovol SV06: Three Months Later

- The Bambu A1 Mini – The Best Choice for Your First 3D Printer

- My Bambu A1 Mini – My First Six Hours of 3D Printing

The Sovol Comgrow T300 is probably faster than the Bambu A1 out of the box

Maybe. We haven’t seen Sovol’s slicer profiles for the new printer. We haven’t seen how fast they actually are in practice, and we haven’t seen the quality of the printed parts. Let’s just assume Sovol has done a reasonably good job here, and that the T300 does what it says on the box.

The speed limit on the A1 and A1 Mini is 300 mm/s with 20,000 mm/s2 acceleration, but none of my OrcaSlicer profiles exceed 10,000 mm/s2 acceleration. You can definitely push this and still get nice prints, but the beauty of the Bambu printers is how well everything works out of the box.

I don’t know what Sovol has chosen for their print speeds, but there isn’t much reason to assume they haven’t pushed things to maybe 350 mm/s or so, and you can bet they are using 12,000 mm/s2 acceleration for infill and travel moves where the A1 is limited to 10,000 mm/s2.

More importantly, the T300 claims to have a hot end capable of melting 30 cubic mm of filament per second. The Bambu A1 Mini defaults to 20 cubic mm per second in the slicer, and my machine tops out at 25 cubic mm per second.

If you upgrade either printer to a 0.6-mm nozzle, you will be amazed at how slowly the tool moves around while maxing out the heat capacity of the hot end.

Thank goodness there’s finally network connectivity!

I am using Marlin’s input shaper on my Sovol SV06. It works great, but Octoprint and the Sovol’s slow serial port have become a bottleneck. I just can’t send g-code as quickly as the printer can move. I can solve this problem with a $100 Klipper screen and then a bunch of tuning, but I would much rather replace the whole thing with a Bambu A1 instead.

I believe the T300’s Klipper hardware has both WiFi and Ethernet. This is good news. You can upload g-code straight to Klipper from your slicer, and you won’t have to shuttle SD cards back and forth like a caveman.

I would expect this to be common moving forward, and that network connectivity will be showing up in cheaper and cheaper printers.

- Marlin Input Shaping on the Sovol SV06: Three Months Later

- The Bambu A1 Mini – The Best Choice for Your First 3D Printer

- My Bambu A1 Mini – My First Six Hours of 3D Printing

Who should buy the Sovol Comgrow T300 instead of a Bambu A1 or P1S?

Almost no one should buy the Comgrow T300. You should almost definitely be looking at a printer from Bambu. It isn’t speed, linear rails, or the aesthetics of the machine that make the A1 and A1 Mini awesome printers.

It is the combination of Bambu’s awesome software with their bleeding-edge sensor technology. These are the things that make Bambu printers a joy to operate, and lead to successful prints right out of the gate.

But as I already said earlier, I would consider the Comgrow T300 if I really, really, REALLY needed a bigger printer than the Bambu A1 or Bambu P1S. I am excited to report that I absolutely don’t need a bigger printer. In fact, I rarely need a printer bigger than my Bambu A1 Mini.

If I did, though, I would make sure to wait and see what sort of success other people have with the Comgrow T300 before I place an order. Sovol is only just barely shipping this printer so far!

Conclusion

I want Sovol to succeed. On paper, they sure seem to have almost all the ingredients necessary to almost compete with Bambu here. If they can spend a little engineering time to ship good, fast slicer profiles that just work, they might be in pretty good shape.

But come on, Sovol! You need to ship a printer with strain-sensor bed leveling. That is the biggest difference between your printers and modern printers like the Prusa MK4 or any printer from Bambu Lab. Having that one feature, and having it tuned to work well eliminates half the problems we see posted to r/FixMyPrint!

This is the killer feature separating Bambu, the Prusa MK4, and the Prusa XL from everyone else. After the horribly named Creality Ender 3 V3 SE shipping with its weird strain-sensor setup, I assumed that we would start seeing every the new model of 3D printer ship with attempts at using strain sensors, but I guess that won’t be happening until the next iteration for Sovol.

What do you think? Are you going to buy a Sovol Comgrow T300? Do you need that extra build volume, or would you be better off with a Bambu A1 or A1 Mini? Are you disappointed that the T300 is missing all the most important current-generation features? Let me know in the comments, or stop by the Butter, What?! Discord server to chat with me about it!