My Prusa MK3S has a problem, and I believe it has had this problem to at least some degree since I bought it. I have trouble getting good first-layer adhesion on certain edges of the bed. If I remember correctly, there is a stretch down the left edge of the bed that is about an inch wide where parts just don’t like to stick. The opposite front corner is also problematic.

I don’t print large parts all that often. When I do, I say a little prayer to Optimus Prime, and I might have to restart the job a few times until it sticks.

I got frustrated with this a while back. I tried tweaking Prusa’s bed level correction, but I just couldn’t get it to a point where I was pleased. I wound up adjusting my profiles in PrusaSlicer to have really wide extrusions on the first layer. This helped a lot, but it wasn’t exactly a fix.

I almost ordered a new PEI sheet, but Prusa branded PEI sheets at Printed Solid are $49.99. My original sheet LOOKS fine. I would feel dumb if I ordered a replacement only to have the same problem again.

tl;dr

The $20 double-sided textured PEI sheet I ordered from Amazon has fixed all my problems. It is textured on one side, and it is smooth on the other. The coatings are close enough in thickness that I can just flip it over without adjusting my first layer calibration.

If you are having problems in certain areas of your stock Prusa PEI sheet, and I think you should just go spend $20 and see if the cheap textured sheet fixes your problems.

- Double-Sided Powder-Coated PEI Sheet at Amazon

Tom Sanladerer’s interview with Josef Prusa got me wondering

The Nextruder on the Prusa MK4 and the Prusa XL is really cool. Instead of using an induction probe to measure the distance to the steel sheet under the PEI coating, the Nextruder senses when the nozzle comes in contact with the surface.

I wouldn’t go so far as to call this a game-changer like the auto bed leveling that was introduced with the Prusa MK2, but it is a nice improvement. During Tom Sanladerer’s interview, Josef Prusa says something interesting about my own PEI sheet that shipped with my Prusa MK3S.

My machine shipped with a build plate where sheets of PEI are glued to a piece of steel. Josef Prusa says that the tolerances of the PEI sheet vary, and the tolerances of the adhesive vary. Is this why my stock PEI sheet has a couple of low spots near the edges?

How long has Josef Prusa known that this hasn’t been ideal? He could have switched to powder-coated build plates when he found out. He could have mentioned this to the community. If he did, I would have immediately spent the $50 on a Prusa-branded powder-coated PEI sheet instead of wasting time trying to tune the problem away.

The Sovol SV06 encouraged me to order something immediately

I have to imagine that the refurbished Sovol SV06 that I bought must have shipped with the cheapest PEI build plate available. It is textured on one side and completely uncoated on the other.

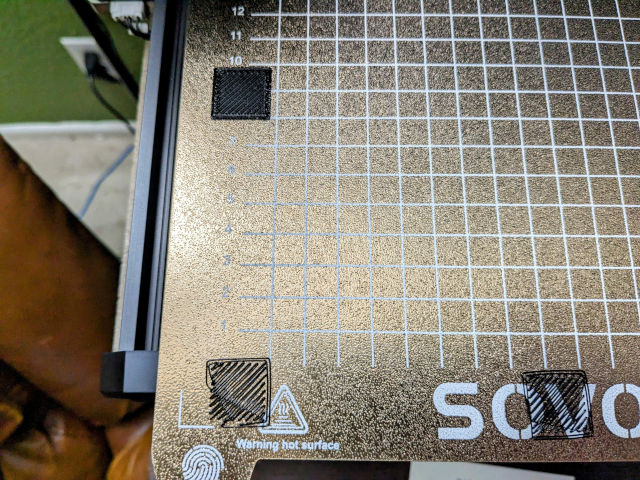

Sovol’s manual suggested adjusting the Z-offset until the nozzle was 0.2 mm above the bed. I dialed it in until it was just touching a 0.3 mm business card, then turned the knob 0.1 mm farther before starting my test print. I ran one of the test models that puts nine squares on the bed.

NOTE: The first square was on the bottom left. I think I did a pretty good job getting close to correct on the final square, which is at the top of the photo. Can you believe the first one managed to stick at all?!

The first square was printed 0.3 mm higher than my final offset. The gaps between the lines of extrusion were huge, but every line stuck to the PEI. Three or four of those test squares would never have stuck on the Prusa MK3S. That first square would have just been a blob of filament dragging behind the nozzle.

That is when I knew I needed to order a cheap textured sheet to try on the Prusa MK3S.

- My Sovol SV06 – Can It Match My Prusa MK3S?

- [Eight Hours With My New Prusa MK3S 3D Printer][mk3s]

I love my cheap PEI sheet, and I am never going back

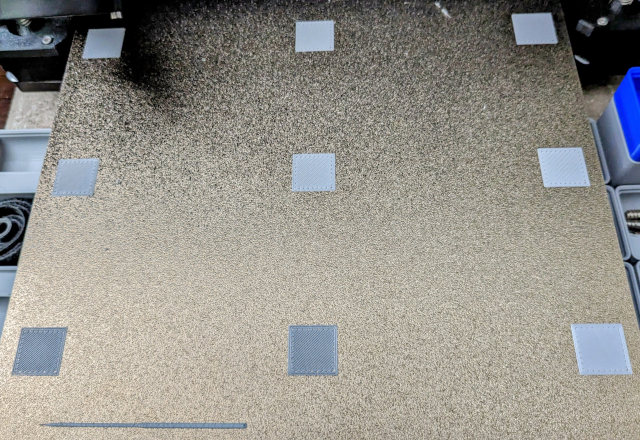

I literally picked the cheapest PEI sheet for the Prusa MK3 that I could find. It isn’t quite as cheaply made as the Sovol plate. The sheet from Amazon is coated on both sides, and the spring steel feels thicker and stiffer.

NOTE: The squares printed counter-clockwise starting from the bottom left. I was really close to correct for the third square, then I overcorrected and got just a little too close to the bed. I am aware that you can’t really tell in the tiny photo. It is mostly just here to show that all four corners and all four edges had no trouble printing correctly.

I would absolutely believe you if you told me that all the powder-coated PEI sheets are made in the same factory. They all have a sort of bronze color. They seem to have the same texture. They are all cheap. Maybe someone is making a better grade of sheet in metallic bronze, but I don’t know how you would tell the difference.

Conclusion

I am only one anecdote with one cheap PEI sheet. I am having a much improved experience over the stock Prusa MK3S build plate, but I want to hear about your experience! Are you having good luck the original Prusa PEI sheet? Or have you also been having trouble getting a good first layer around the edges? Did you try a powder-coated sheet? How is it working out for you? Did you go cheap like I did, or did you buy a powder-coated sheet from Prusa? Let me know in the comments, or stop by the Butter, What?! Discord server to chat with me about it!

- Double-Sided Powder-Coated PEI Sheet at Amazon

- One Weird Trick To Use When Your First Layer Won’t Stick

- My Sovol SV06 – Can It Match My Prusa MK3S?

- [Eight Hours With My New Prusa MK3S 3D Printer][mk3s]

- I Am Worried About Prusa Research