There is just so much to like about the Sovol SV08 on paper. A solid-looking Voron clone running Klipper with a massive 350 mm cube of build volume for under $600 is a really good value. It is a good value even if Sovol misses the mark in a lot of other areas, and they have sure missed a few important targets that every modern printer should be meeting.

I think we should talk about the potential problems with the Sovol SV08 first. If you’re buying your first 3D printer, you should most definitely know what you are getting yourself into. Sovol has more than a little sneaky verbiage sprinkled around the Sovol SV08 listing that makes it sound like it matches the Bambu printers and the Prusa MK4 in the most important ways, but the SV08 just doesn’t have the sensors to pull off the same fantastic usability tricks.

There are definitely some things you should think about before paying to be an alpha tester for Sovol’s latest printer.

- Sovol SV08 at Sovol.com

- The Sovol SV06 – Is It Still Worth Buying in 2024?

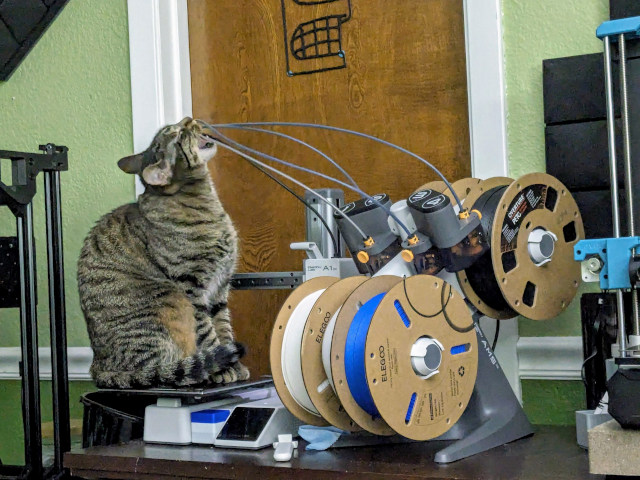

- Bambu A1 – Can Your 3D Printer Pay For Itself In 2024?

- I bought another 3D printer, the Bambu Labs P1S at Brian’s Blog

Strain-sensor bed leveling should be table stakes in 2024

The Bambu X1C started shipping about two years ago. It uses strain sensors mounted in the bed to detect when the tip of the nozzle makes contact with the surface of the bed. The Prusa MK4 started shipping about a year later with a single strain sensor in the hot end to serve the same purpose. Then late last year, the Bambu A1 Mini shipped with a similar strain sensor setup in the nozzle.

The Prusa MK2, Prusa MK3, Sovol SV06, and Sovol SV08 all use an inductive probe to generate the mesh to level the bed. The inductive probe can’t detect the PEI surface. What it can detect is the steel sheet beneath the PEI surface. That means that the operator of the 3D printer needs to manually dial in a correction to account for the thickness of that PEI surface, and you will have to make this adjustment every time you swap in a new print surface.

Lost In Tech’s review is the one that made me more optimistic about the Sovol SV08!

The Sovol SV08 does use a strain sensor. That strain sensor is mounted on the bed, and it is used to allow the printer to account for the variances in the induction probe that are caused by temperature changes. This strain sensor can not figure out how thick your sheet of PEI is. You will still have to calibrate for that yourself.

Why is this a big deal? The Sovol SV08 is using seven-year-old bed-leveling technology. If Sovol put a strain sensor in their new hot end on the SV08 and T300, they would have eliminated a HUGE source of error. The vast majority of new-user problems posted in r/FixMyPrint and [r/Sovol] would be eliminated if Sovol used a strain sensor in the toolhead.

It is a bummer that Sovol missed the boat, but simply having a strain sensor in the right place wouldn’t mean that things would be perfect. Creality is using a strain sensor to eliminate the need to calibrate your z-offset on the latest Ender 3, but it doesn’t seem to work nearly as well as Bambu’s or Prusa’s strain-sensor bed leveling. There is some software engineering that has to happen as well!

Is this a deal-breaker? Definitely not. Inductive probes are a solid bed-leveling technology, and you should only have to dial in that Z-offset once, but dialing it in the first time is tough if you have never done it before.

Sovol has included that extra sensor to help compensate for the variance in the inductive probe, and it looks like it does a fantastic job at compensating. This will be a nice improvement over the Prusa MK3 and [the Sovol SV06][sv06is]. The trouble is that Sovol hasn’t included this functionality in their firmware or slicer profiles. Lost in Tech has a great video talking about implementing this functionality in Klipper, and it looks like it works great once you get it working.

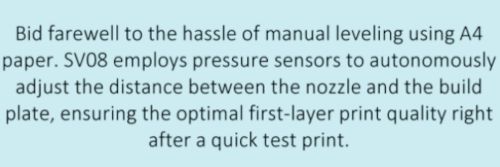

NOTE: This is a screenshot of Sovol’s own words from the Sovol SV08 page on their website as of April 26, 2024.

Their marketing material strongly implies that you don’t have to worry about dialing in your first layer, but they sure don’t seem to have the appropriate sensor configuration to make that happen. The first four lines of copy in that screenshot make it sound like you will have a Bambu-style experience, but the last line suggests this is probably not the case. It feels a little slimy.

- Sovol SV08 at Sovol.com

- The Sovol SV06 – Is It Still Worth Buying in 2024?

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

You are paying Sovol to be one of their alpha testers

As is often the case, Sovol has built a rather nice piece of hardware, but they haven’t put in the time to tie it all together with well-tuned software.

Sovol has been known to do a reasonable enough job on the software side in the past. They modified Marlin just enough on their SV06 to support Prusa’s slightly odd G-code changes. It worked well enough that you could literally pretend that your Sovol was a Prusa MK3. I just duplicated my Octoprint VM, plugged my Sovol SV06 in, and started using my existing PrusaSlicer profiles. If you just tell your slicer that you were using a Prusa MK3, then your Sovol SV06 would just work.

As far as I can tell, the Sovol SV08 is shipping with the bare minimum of software support. There is a single slicer profile for PLA. The extra bed-leveling sensor isn’t utilized. Things are just not quite ready yet.

Will Sovol put in the work to build a software ecosystem for their new printer, or will they leave that for the community to worry about? Will they move on to the next model instead?

Do you really need a coreXY printer?

If you want a coreXY printer just because they are cool, that is fine. Buy the Sovol SV08 or Bambu P1S right now! If you want to buy a printer that is fast and accurate, coreXY really isn’t necessary these days.

Yes, these machines can run faster than a bedslinger, and they can be upgraded and tuned to run ridiculously fast. That said, bedslingers have gotten really fast now. Not nearly as fast as the fastest SpeedBoatRace Vorons, but a Bambu A1 or A1 Mini will for sure give the new Sovol SV08 a run for its money. The Bambu and Sovol are both usually going to be limited by the flow rate of their hot ends, and they are pretty comparable there.

When I bought my Prusa MK3S, I assumed my next printer would be a coreXY. Then everyone started using input shaping on their bedslingers, and the extra potential performance didn’t matter as much. I would still like to own a coreXY printer, but I don’t have much good reason to pay extra for one.

- Sovol SV08 at Sovol.com

- I bought another 3D printer, the Bambu Labs P1S at Brian’s Blog

The Bambu A1 vs. the Sovol SV08

The Sovol SV08 looks like it wants to compete with the Bambu X1C or P1S, but the lack of multimaterial support and the price point put it in practical competition with the Bambu A1. These two printers are priced the same if you include the AMS with the Bambu A1, or the A1 is $150 cheaper.

These comparisons are always apples to oranges. No two companies sell printers with directly comparable specs. The Bambu A1 comes with an AMS at the same price, but the Sovol SV08 is significantly larger.

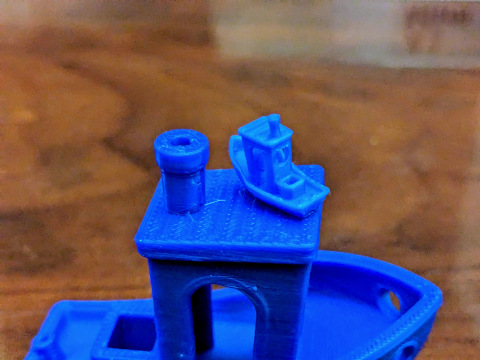

Tiny 3DBenchy printed with a 0.2 mm nozzle on the Bambu A1 Mini with zero tuning

The most important thing I can say about Bambu here is that they aren’t making you be an alpha tester. Pretty much everything is well tuned and just works during the entire workflow from STL to completed print. Their slicer profiles are well tuned, especially if you stick with a 0.4 mm nozzle and common materials. Their printers all make sure you get a perfect first layer, and the A1 and X1C are both able to dial in your flow rates and pressure advance to help get that last inch of quality out of your parts. It is all easy to use, and this process was tested, tuned, and completed before you even thought about ordering the printer.

I repeat this over and over and over again because it is so important. Bambu’s and the Prusa MK4’s bed-leveling implementations are awesome for pros and absolutely amazing for beginners. This feature alone solves the vast majority of new-user problems posted to r/FixMyPrint.

If you have never used a 3D printer before, this is the feature you need. It can save you many hours of frustration. This could very well be the difference between having a fun time or wanting to smash your new toy to pieces with a sledge-hammer.

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

- I bought another 3D printer, the Bambu Labs P1S at Brian’s Blog

Who should be looking at the Sovol SV08?

I absolutely believe you should buy a printer from Bambu. I think the Bambu A1 Mini is a fantastic printer at an amazing price, with or without the AMS Lite. I have been using mine since early December. It is a small printer, but I have only had to fire up my Sovol twice since then to print things that wouldn’t fit on the A1 Mini.

Some of you reading this will just need a bigger printer. The Bambu A1, P1S, and X1C are way bigger than my Bambu A1 Mini, but they are only just barely big enough to print a full cosplay helmet. The 300-mm bed on the Sovol Comgrow T300 would give you a significant amount of wiggle room there, and the 350-mm bed on the Sovol SV08 may even be a welcomed upgrade for you.

A 1x1 Gridfinity bin tucks perfectly into that slot on the Bambu A1 Mini, so I printed a T-shaped grid to fit right in!

If you have a solid use case for a huge printer, then the Sovol SV08 sure looks like a good compromise on performance, quality, and price.

You probably don’t need a printer as big as the Sovol SV08 or even the Sovol T300. You can get a Bambu A1 for about the same price.

You won’t be alpha testing a printer. You’ll be buying a proven piece of hardware with a buttery-smooth printing workflow. You’ll be trading the Sovol SV08’s increased size for better bed-leveling technology that works perfectly almost every single time, and you’ll be getting snazzy flow-rate sensors that almost guarantee perfect prints.

- Sovol SV08 at Sovol.com

- Sovol Comgrow T300 at Sovol.com

- The Sovol Comgrow T300 Only LOOKS Like a Bambu A1

Is setting a Z-offset and dialing in flow rate really that hard?!

It isn’t difficult. I had my Z-offset dialed in on my Sovol SV06 in less than five minutes, and as long as you err slightly on the side of underextrusion, dialing in flow rate isn’t challenging. You have to get the Z-offset almost perfect, but flow rate can be off by as much as 10%, and you might never notice.

I have manually leveled beds on a dozen different models of printer. I have been dialing in Z-offsets for years. Every time you do it, it gets easier.

Do you know what the trouble is? Someone buying their first printer doesn’t know what to look for when they are adjusting the live Z during the test print. If you know what you are doing, it is really simple. All you have to go on is a few paragraphs of explanation, some YouTube videos, and a hope that you understood what things should look like.

The Sovol SV08 is for tinkerers

For some people, the 3D printer is the hobby. For others, the 3D printer enables or supplements their other hobbies or work. Most of us will likely wind up falling somewhere in between, but I bet most of you want to print more and tinker less.

We all had no choice but to tinker in order to operate a 3D printer ten years ago. Now you can buy a Bambu A1 Mini, spend 10 minutes snapping the AMS Lite together, and be printing in almost no time at all. It is a delightful experience.

The Sovol SV08 is a cheaper and much easier to assemble version of the Voron, and that is absolutely amazing. I always wanted to own a Voron, but the thought of spending more than $1,000 on a kit, having to 3D-print all the parts myself, and then having to spend a full weekend of my time assembling it before I could even hope to begin dialing it in didn’t seem like fun. Especially when you can spend half as much on a Bambu P1S and be printing in twenty minutes.

The Sovol SV08 looks SO much easier to assemble than a Voron or Prusa MK4, so it reduces the required amount of tinkering by orders of magnitude compared to a Voron. The printer hardware looks capable out of the box, but these Voron-style printers tend to attract tinkerers, so there’s a very good chance you’ll want to modify something on yours.

Even if you don’t modify the hardware, you are going to have to tinker with slicer profiles and Klipper macros. Sovol does not set you up for success here like Bambu and Prusa would. You currently have the bare minimum in software support to get you going. You will be relying on the community and your own know-how to get good, fast, clean prints.

There is nothing wrong with that. It is important that you know what you are getting into.

The Sovol SV08 is open-source

This is heckin’ fantastic! At first, I was worried that this would only apply to the Klipper firmware, but then I saw the Klicky Probe for the Sovol SV08 on Printables, and it is obviously designed around existing models of the Sovol SV08.

I am a huge fan of open-source. I have been running almost entirely open source software at home since the late nineties, and nearly as long in my professional life. Open source is one of the reasons why I chose to buy a Prusa MK3S, but Josef Prusa is trying to weasel his way out of open-sourcing as much as he can get away with now, so the Sovol SV06 and Sovol SV08 may both be more open printers than the Prusa MK4.

The closed ecosystem behind Bambu’s printers is easily their biggest downside. If Bambu disappeared tomorrow, which is becoming less and less likely every day, you wouldn’t be able to buy parts to repair your printer in the future. There are oodles of custom parts on these printers. That is no small part of why they are able to price their printers so aggressively.

If Sovol goes out of business tomorrow, and Bambu’s continuing success and extremely aggressive pricing makes this likelier than ever, you will still be able to repair your Sovol SV06 or SV08. So many of the components are common off-the-shelf parts. We have STL files for all the injection-molded parts, so we can 3D-print replacements. There is a future here even if the manufacturer goes away.

Final thoughts

The Sovol SV08 and its similarly priced competitors really are apples and oranges. The printers from Bambu are well-oiled machines with smooth workflows. They are a lot like having a small manufacturing department in your home office. You can send stuff to your manufacturing robot, and it will usually just do a good job with zero interference from you. You should still take a peek at it from time to time, but your Bambu prints are likely to just work the vast majority of the time.

The Sovol SV08 will be more like an intern fresh out of school. Sure, it is a bigger employee who can print larger things, but the SV08 is untested. You are going to have to help him along for quite a while. You’re going to have to ask your friends for advice on how to mold your new intern into the sort of employee you want to have around. It isn’t fully baked. At least, not yet!

What do you think? Are you shopping for your first 3D printer? Or are you a veteran looking to add another printer to your farm? Do you agree that the 256 mm printers from Bambu are worth the living with the smaller size for all the usability features? Or do you think it is super important to have that 350 mm print bed? Let me know in the comments, or stop by the Butter, What?! Discord server to chat with me about it!

- Sovol SV08 at Sovol.com

- Sovol Comgrow T300 at Sovol.com

- The Sovol SV06 – Is It Still Worth Buying in 2024?

- Marlin Input Shaping on the Sovol SV06: Three Months Later

- Bambu A1 – Can Your 3D Printer Pay For Itself In 2024?

- The Bambu A1 Mini is So Good I Had to Delete an Entire Blog Post!

- The Sovol Comgrow T300 Only LOOKS Like a Bambu A1

- I bought another 3D printer, the Bambu Labs P1S at Brian’s Blog