I have listed the 3D printed Li’l Magnum! mouse mod kit in my Tindie store. I would prefer that you print your own. I would be excited if you would use this as an opportunity to spend $180 on a Bambu A1 Mini 3D printer so you could print a Li’l Magnum! for yourself and your friends, but I also understand that not everyone can or would even want to own a 3D printer, and I would like to see more people trying out the Li’l Magnum! for themselves.

I would also concede that I would be able to buy more models of donor mice if enough people are buying Li’l Magnum! kits from me. The more unique mice I can buy, the more mice I can support with the Li’l Magnum! shell.

That seems like a win for everybody, and it gets me closer to my goal of democratizing ultralight fingertip mice! It would be nice if you didn’t even have to buy a mouse. If I make the Li’l Magnum! compatible with enough donor mice, then there will be a good chance that you already own the necessary hardware.

- Li’l Magnum! Fingertip Mouse Mod in my Tindie store

- VXE Dragonfly R1 Series mice at Aliexpress

- VXE Dragonfly R1 Series mice at ATK.store

Don’t judge your new mouse too quickly!

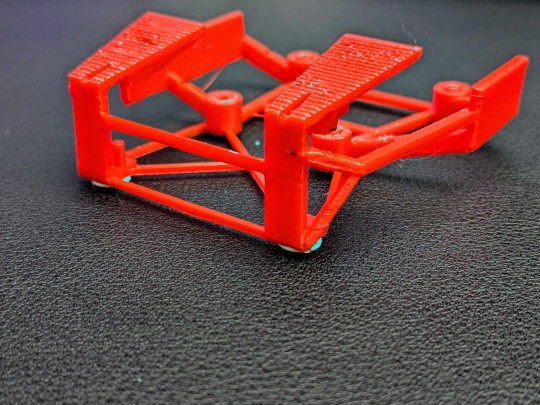

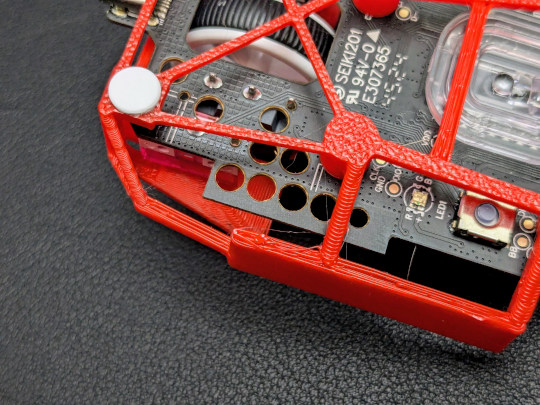

Most of my Li’l Magnum! mods use less than three grams of plastic now. They feel quite flimsy on their own. They borrow most of their rigidity from the PCB once it has been installed!

Even after, though, using a mouse like this was a weird experience for me. I kept wanting to squeeze, flex, and press different parts of the first Li’l Magnum! as I was playing. I hardly doing that at all by the second or third day.

If you haven’t used a lightweight mouse before, you will notice that your aim is going to get worse before it gets better. Using a mouse that is 60 to 80 grams lighter is a shocking experience. It takes time to acclimate.

I stopped noticing the 3D-printed shell after a week or two. It is just feels like this is how it is supposed to be now.

You may very well wind up learning that you just hate fingertip mice, hate ultralight mice, or both! I was worried that I wouldn’t like using a 20-gram mouse, so I made sure to design the Li’l Magnum! to work with a $20 donor mouse. That keeps the cost of trying something so radically different as low as possible, and if I hated the ultralight mouse, I could put the original 49-gram mouse back together.

Are you really selling PLA printed on your home FDM 3D printer?!

Yes.

I assumed that I would only be prototyping the Li’l Magnum! using PLA filament. I thought that I would quickly switch to PETG or ABS, and from there I might start sending out of nylon prints from an SLS or MJF machine.

It turned out that the PLA prints work working amazingly well, and my first ABS test mouse was brittle and way too spongy. That was when I realized that the shape and thickness of the button paddles would need to be adjusted for different materials.

That led me two a pair of conclusions. First, I would be spending a lot of money sending out for test prints from an MJF printer just to dial everything in. I also realized that if we’re going to be democratizing custom mice, then we need people to be able to print the Li’l Magnum! at home. Everyone who owns a 3D printer can print PLA.

I could either focus my attention on dialing in the dimensions for a good feel with ABS and nylon, or I could just assume everyone should be printing the Li’l Magnum! in PLA and put all my work into optimizing for that.

Then I strapped one of my prototype shells to my Lumen pick and place machine and set up a script to click the button as fast as it could. I let it run for more than 30 hours straight, and the LumenPNP clicked that button more than 1.2 million times. The Li’l Magnum! still felt brand new, so I feel like PLA is up to the challenge.

What should you expect to see when you receive your Li’l Magnum! shell?

The Li’l Magnum! is balancing in a precarious spot between being just durable enough to not break, stiff enough to feel right in your hand, while also being as light as I can possibly make it. We are also fighting some of the limitations of the FDM 3D-printing process and gravity.

I have been gaming with nothing but one iteration or another of the Li’l Magnum! for the last six weeks. It fits my hand well. It does have some flex when you squeeze the sides hard enough, but I feel that it is more than stiff enough for the job.

The underside of the finger grips will be slightly imperfect because they have to be held up by support material when printed. The same is true of the underside of the buttons.

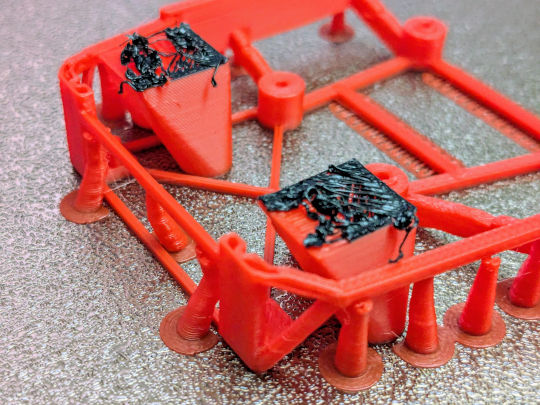

NOTE: I’ve switched to using zero-clearance PETG supports directly under the button plungers, so they print perfectly now. I am working to verify that the change in filament isn’t contaminating the PLA and making the buttons brittle. I expect we are in good shape, and I believe I will be shipping out perfect plungers from now on!

See that tiny black dot? That is PETG support material accidentally dropped into the PLA, and it ruined the integrity of this print. That button snapped right off while trying to insert the PCB. I believe I have eliminated this problem completely.

There will also be slight imperfections on the bottom of the angled arms that connect the grips to the body. These are printed without support material, but they are at an extreme enough angle that they are just on the edge of being printable without supports. I have printed them both ways, and I think they look cleaner without supports.

Removing these supports leaves a slight discoloration behind. I prefer the ever so slightly uneven surface to the whitening of the plastic.

There will also be a stair-step texture on top of the buttons. This is caused by the 0.16-mm layer height that I have optimized for. I like this slight texture under my fingers, but I could understand why others might not feel the same way. I cut pieces of grip tape to fit my buttons, and I was running the Li’l Magnum! like that for a week. It was nice, but I preferred the bare plastic.

I don’t believe that any of this is bad, but I do think it is important to set expectations. These are not injection-molded mouse shells. These are more like custom FPV drones.

I can pay a 3D-printing service less to print a Li’l Magnum!, why should I buy one from you?!

I would first like to tell you that I didn’t put a ton of thought into the $20 price. It is a round number, it is a little more than one quarter of the price of the original Zeromouse kit, and it is half the price of some of the other 3D-printed ultralight mouse mods that I have seen. If anything, it feels a little on the inexpensive side.

I didn’t check how much a print farm might charge for a Li’l Magnum! print, but I assume they’d be able to send you a 3-gram part at a REALLY low price.

I am not a print farm. I designed the mouse that I am printing. I know what it is supposed to look like. I know how it should feel. I know what can go wrong. I will be sending you something that I am confident will work as intended.

You’re not just paying for a mouse. You’re paying for the 70 prototypes that I printed and tested up to this point, and the prototypes I will continue to print. You’re paying for the hours I spent in OpenSCAD so I could upload an open-source design for the world to use. You’re helping to pay for all my future improvements.

NOTE: I am a little behind on publishing a Git repo of the OpenSCAD source code. There are a lot of plates I am attempting to get spinning: the blog posts, the MakerWorld and Printables pages, the Tindie listing, this post to link from Tindie, YouTube videos, and finally a Git repo. I can only work on getting one plate up into the air at a time, but the GPL v3 repo should be somewhere soon!

I am not Logitech. I won’t sell enough mice that a nickel from every mouse sold will pay an engineer’s salary. I am just a guy with a blog, an underutilized YouTube channel, a 3D printer, and a dream.

I just spent eight hours perfecting the print settings for the button plungers!

The Li’l Magnum! has been in my Tindie store for less than a week, and I was about to put the finishing touches on this blog post to publish it today. Then I had an idea.

I really want to print the plungers on top of zero-clearance PETG supports, but Orca Slicer just doesn’t want to let me do it the way I want.

I need some automatic tree supports sprinkled around the grips and base, but if I have the extremely long purge to keep PETG from mixing with PLA in the print, then I am going to waste tons of filament and time. I am already wasting more than the weight of an entire Li’l Magnum! on a single change to PETG.

I have had half a dozen failed prints trying to bend things to my will. The slicer just won’t let me mix traditional supports topped with solid PETG with PLA tree supports. I wound up designing my own support piece into the model, and I used manually placed modifiers to set up which parts should be PETG, and which bits of PLA needed to be solid.

My first couple of attempts at manually building a PETG support interface failed. The extra narrow extrusion width I use to keep the weight down wasn’t conducive to helping the PETG squish down on the PLA that it already doesn’t want to stick to!

Then I discovered a whole new problem. When printing with regular PLA supports on a PLA print, there is a 0.2-mm gap between the top of the support and the bottom of the plunger. This means that my plungers technically print slightly lower than what I set up in the model.

My prints with the dialed-in PETG supports with zero clearance are coming out with immaculate plungers. There is little to no black PETG left under the PLA plunger, and all my supports almost fall right off.

The trouble is that the plungers were too high! I had to spend another 90 minutes printing and adjusting the model and modifiers two more times to get things feeling right. This means that I will need separate models with different button heights for people who want to use basic PLA supports and people who want zero-clearance PETG supports.

This is another of those things that a print-on-demand service wouldn’t know about.

The PETG supports have increased the print time by 20%, and I am burning through a few pennies in extra material. The time that I have to spend cleaning up the print afterwards has gotten really close to zero now, so I think this is a fantastic trade!

Why can’t you buy a fully assembled Li’l Magnum!?

I would love to be able to order a big box full of the guts for dozens or hundreds of mice from VXE or ATK so that I could sell you a working, tested, functional Li’l Magnum! that you could plug in and start using immediately. I haven’t figured that out yet. I don’t even know if enough of you would be interested in purchasing mice to know if it is worth taking the risk.

I have had great luck with my prints over the last couple of weeks. All the recent STL files print well, and the clicks feel great almost every single time. I expect the clicks will always be perfect now that I am using zero-clearance multimaterial supports for the plungers.

The real trouble is that I only have one of each PCB. Yours might have slightly different tolerances. There is a slim chance that you will need to shim underneath your PCB with a layer of tape to tighten up the clicks.

There is also the chance that the manufacturers will get sneaky. They might slip a slightly different PCB into an existing mouse, and that new PCB just doesn’t quite work with the Li’l Magnum! that I ship you, because I wasn’t aware of the change.

I would love to be able to test the clicks on every Li’l Magnum! before sending them out. It would be nice to know that I paired the right PCB with the right print for perfect clicks every single time. I will be excited if I can get to that point in the future!

What donor mouse do I have to buy to build a Li’l Magnum!?

Let’s start with the table of all the mice that I have been working with:

| Mouse | $ | Grams | Other | |

|---|---|---|---|---|

| R1 SE | $19 | 21.3g | Worse lens | |

| R1 SE+ | $23 | 25.6g | Worse lens | |

| R1 | $10 | ????? | 4K extra | |

| R1 Pro | $43 | 20.6g | 4K extra | |

| Mad R | $43 | 16.5g | 8K included | |

| Mad R Major | $63 | ????? | Better sensor | |

| McHose L7 Ultra | $66 | 17.9g | On Amazon | |

| Katar | ??? | 26.0g | Outdated |

- VXE Dragonfly R1 Series mice at Aliexpress

- VXE Dragonfly R1 Series mice at ATK.store

I have been focusing on the mice from VXE/ATK. They are popular and lightweight. They do well in latency tests, and the configuration GUI works in Chrome on Linux.

I was drawn to the VXE’s Dragonfly R1 series specifically because of that $19 R1 SE. I was absolutely tickled by the idea that you could spend $19 on a mouse, 3D print a 3-gram shell, and you could inexpensively discover whether or not you’re even interested in using an ultralight fingertip mouse.

I was also excited that the lineup didn’t stop there. The R1 Pro has a better sensor, nicer buttons, and its electronics weigh slightly less. It is even better that the R1 Pro doesn’t even cost much more!

My VXE Mad R finally cleared customs and arrived here yesterday, and it is amazing. The Li’l Magnum! needed very little modification to make its PCB fit, and every part of the Mad R is lighter than the R1 Pro. The battery is 1.2 grams lighter, thought it is also has slightly less capacity. The wheel is more than a gram lighter. The PCB is lighter.

My VXE Mad R Li’l Magnum! weighs 16.47 grams. That is 4.2 grams lighter than my VXE R1 Pro build, and I paid roughly $43 each of those mice.

The VXE Mad R also ships with an 8K receiver and upgraded optical switches.

My opinion is that there are only two donor mice to choose between. The VXE Dragonfly R1 SE is a fine mouse for $19, and it comes out to just over 21 grams when installed in a Li’l Magnum!, and 21 grams feels ridiculously light. If that isn’t good enough for you, skip all the other R1 models and go with the VXE Mad R. You get so much for your money there!

I expect that the Mad R Major with its upgraded sensor will fit in the Mad R version of the Li’l Magnum!. I don’t have one here, but I hope some brave soul will test it out for us and report back!

I don’t want to wait for a mouse to ship from China

I picked out a nice mouse from Amazon. It is the McHose L7 Ultra for $66. The specs are very much in line with the VXE Mad R Major. It looks like they both use identical optical switches, the same ultralight wheel, and the low-profile rotary encoder.

The McHose L7 Ultra uses the PAW3950 42K DPI sensor, just like the Mad R Major, so that is an upgrade over my own Li’l Magnum! built around the base model Mad R. Everything in the McHose L7 is lightweight, but the VXE Mad R has an advantage of about one gram due to its slightly smaller battery.

I wouldn’t worry about a single gram.

My copy of the McHose L7 is the Ultra. There is a slightly cheaper L7 Pro that uses the PAW3395 26K DPI sensor just like my Mad R and R1 Pro. There is a good chance that any trim level of the McHose L7 will drop into the Li’l Magnum! shell, but I don’t have the other two on hand to verify that.

Conclusion: Democratizing Ultralight Mice Starts Here

The Li’l Magnum! isn’t just a product—it’s a movement. By bridging 3D printing, open-source 3D models, and gaming hardware, we’re tearing down barriers to ultralight mouse ownership and customization. No more eye-watering price tags. Whether you print your own shell or grab a kit from my Tindie store, you’re part of a community proving that high-performance gear doesn’t have to cost a fortune.

Every Li’l Magnum! kit sold isn’t just a transaction—it’s fuel for the bigger mission. Your support lets me test more donor mice (like the newly acquired Mad R!), refine designs, and expand compatibility across models. PLA prints might not be the ideal material, but they’re affordable, accessible, and battle-tested.

This isn’t about chasing profit margins. It’s about passion, prototypes, and persistence. It’s about empowering you to build a mouse that fits your hand, your playstyle, and your budget. From $19 budget builds to more premium $60 mods, the goal is simple: ultralight mice for everyone, no matter the budget!

Let’s keep the momentum going.

Join our Discord community to share your Li’l Magnum! builds, swap tips, and help shape the future of open-source mouse mods. Whether you’re a tinkerer with your own printer or a gamer curious about fingertip grips, your voice matters here.

Together, we’ll keep pushing boundaries, breaking norms, and democratizing ultralight mice—one print, one mod, one click at a time. Ready to lighten up? Let’s go! 🖱️🚀

- Li’l Magnum! Fingertip Mouse Mod in my Tindie store

- The L’iL Magnum! Fingertip Mouse Is Now Customizable on MakerWorld!

- Ultralight Fingertip Gaming Mice – Two Weeks With My 21-Gram L’il Magnum

- Can We Compete With The Zeromouse For Under $25?

- Li’l Magnum! 22-Gram 3D-Printed Fingertip Mouse Mod For The VXE Dragonfly R1 and R1 SE

- Li’l Magnum! Fingertip Frame for VXE Dragonfly R1 Pro at MakerWorld

- Li’l Magnum! Fingertip Frame for VXE Dragonfly R1 Pro at Printables

- Li’l Magnum! Fingertip Frame for VXE Dragonfly R1 / R1 SE at MakerWorld

- Li’l Magnum! Fingertip Frame for VXE Dragonfly R1 / R1 SE at Printables