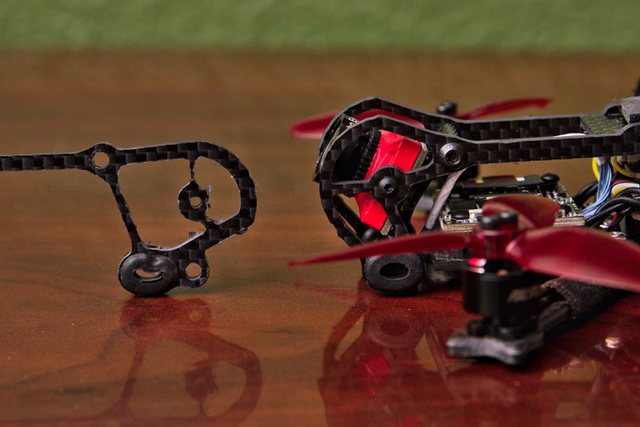

The list of materials you can cut with a CNC router seems endless. Wood is very common, and it looks like my Shapeoko XXL can even manage to handle aluminum. I didn’t buy a CNC machine to cut either of those materials. I’m sure I’ll find some excused to do some woodworking projects in the future, but I bought my machine to cut carbon fiber quadcopter frames!

If your CNC machine can handle hardwood or aluminum, you shouldn’t have any trouble cutting carbon fiber sheets. You certainly don’t need a machine as big or as powerful as the Shapeoko or an X-Carve. You could definitely replicate my success with a small machine like my friend Alex’s SainSmart 3018 Prover CNC.

- I Bought a CNC Machine: I Have No Idea What I’m Doing

- Using MeshCAM For Your First 3018 CNC Project

- My Open-Source 3-inch HD Micro Quad Frame – The Kestrel

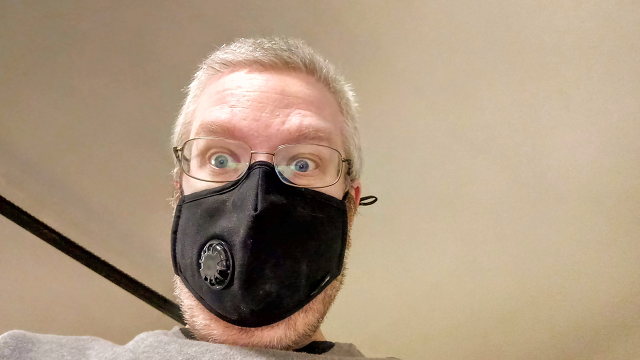

Safety first!

Carbon fiber dust is hazardous. It is conductive, and it gets all over everything. The dust might manage to short circuit something in your laptop. It will get into your router. It will get in your lungs.

That last part is the scary part. Take lots of precautions. Wear a mask. Keep the garage door open, and point a big fan over your machine and out the door. Better yet, pick up the machine and take it out into the driveway!

I wear a mask, and I’m constantly running my little Shopvac knockoff. I would give you a link to the mask I’m using, but I doubt it is really up to snuff. It has a filter, and it doesn’t leave any gaps around my nose. To be properly safe, I should probably look like Barbeque from G.I. Joe.

If I end up doing this often enough, I plan to build an enclosure for my Shapeoko. I’ll put a blower on that enclosure, and I’ll plumb it up to a dryer vent. I haven’t gotten that far along, though.

Be safe. Do your best. Do a better job than I am!

Tell me about these carbon fiber sheets!

I’m not an expert, but as far as I know, there are two common ways to work with carbon fiber. You can shape the woven fabric, then coat it with epoxy. This is a lot like repairing a fiberglass hot tub.

Cutting carbon fiber! Woo! pic.twitter.com/Qami6e7iAk

— Pat Regan (@patsheadcom) February 11, 2019

Quadcopter frames are cut from premade sheets of carbon fiber. The factory stacks layers of carbon fiber, and they impregnate it with epoxy resin. The process generates flat sheets. The sheets I’m using have alternating layers with the carbon fibers rotated 90 degrees. The top and bottom layers have the woven pattern.

The sheets I’m using today are 1 mm, 2 mm, or 3 mm thick.

- I Bought a CNC Machine: I Have No Idea What I’m Doing

- Using MeshCAM For Your First 3018 CNC Project

- My Open-Source 3-inch HD Micro Quad Frame – The Kestrel

This stuff is really sturdy! Is it hard to cut?

Carbon fiber is actually quite easy to cut. Your router doesn’t need a ton of torque or speed—my router’s minimum speed is actually too fast!

My feeds and speeds

This is probably the tl;dr section of this post. How do I cut carbon fiber sheets?

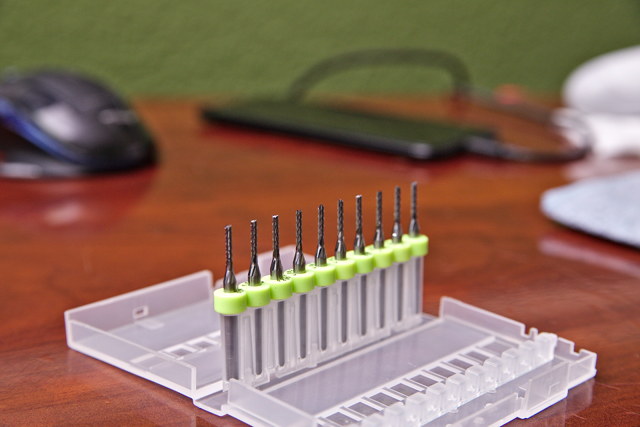

I’m using 1/16” fishtail endmills that I bought on eBay. They’re about $20 for a pack of 10. I haven’t broken one yet, but I will be sure to keep pushing my feeds higher until I do!

These are my current settings:

- Depth per pass: 0.8 mm

- Feed rate: 320 mm/minute

- Plunge rate: 100 mm/minute

- Router speed: 1 on the Dewalt DWP611

I’ve tested all sorts of settings. I’ve gone as high as 800 mm/minute with a cut depth of 0.5 mm. I broke a $20 bit from Carbide 3D on that cut. I’m not sure the speed was the problem, though. My 3 mm carbon fiber sheet came loose during that cut, and I assume that put a lot of stress on the bit.

The math says I should be running my router at 5,000 to 6,000 RPM. My Dewalt router can’t run that slowly. I believe the lowest setting works out to around 20,000 RPM. Too much speed generates heat, and it cuts out dust instead of chips. The heat could be bad for the epoxy, but it hasn’t been problematic yet!

I chose a depth per pass of 0.8 mm, because I’m cutting 3.2 mm deep on my 3 mm sheets of carbon. That means I can cut all the way through a single sheet of carbon in four passes. Choosing your depth per pass based on the thickness of your material seems smart!

My parts are coming out clean and smooth, and I don’t need to do any cleanup afterwards.

I can reduce my number of passes to three if I increase the depth per pass to 1.1 mm. I plan to test this, and I will also be increasing my feed rate.

How much cutting have you done so far?

I am not an expert. I have cut about three quadcopter frames’ worth of parts. Not three complete frames, though. My design process is iterative, so I’ve been replacing parts as I make improvements.

I’ve used up almost half of my first 400x500x3 mm sheet of carbon fiber, and I’ve ordered a less-expensive second sheet from another vendor!

The 400x500 mm 3K carbon fiber sheets are definitely high quality. I ordered those from GetFPV.com. I ordered another sheet of 3 mm 3K carbon fiber from Hobby King. That sheet hasn’t arrived yet, and they don’t stock 400x500 mm sheets. Their prices are quite a bit better, though. You get about 40% more material for your dollar at Hobby King.

I’ll have to crash the new, cheaper sheet to see how sturdy it is!

- I Bought a CNC Machine: I Have No Idea What I’m Doing

- My Open-Source 3-inch HD Micro Quad Frame – The Kestrel

Conclusion

I don’t know why, but I thought this would be a longer blog! I guess there’s not much to say. These are my feed rates. These are the bits I’m using. This is the carbon fiber I’m cutting. The cuts are clean. Done. Right?

I plan to push my feed rates and depths as high as I can. That’s just what I do. I pushed my 3D printer as fast as it could go. I push my quadcopters as fast as they can go. So why not push my Shapeoko as fast as it can go, too?!

Are you cutting carbon fiber on your CNC router? Are you having as much success as I am? I’d love to hear about your machine and your process! Leave a comment a below, or stop by [our Discord server][bw] and chat with me about it!