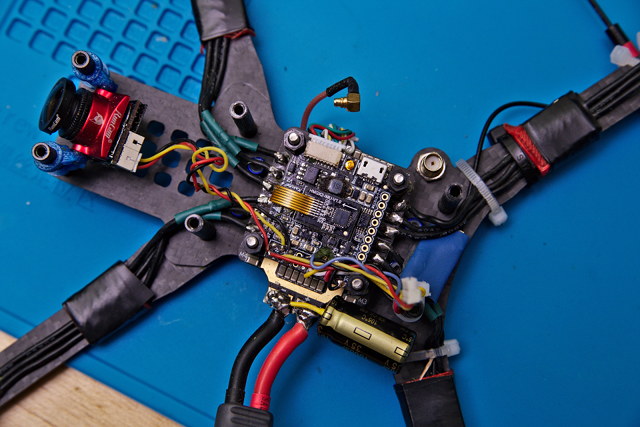

I built the first of my 2018 quadcopters in October of 2017. It was an OwlRC Dragon frame with individual Wraith32 ESCs, a Kakute F4 flight controller, Holybro AtlAtl VTX, and a Runcam Eagle 2 with a set of T-Motor F40 Pro v2 2600 KV motors. It was built to fly on my existing collection of 4S batteries, but all of the components were capable of handling 6S batteries.

So of course I had to try a 5S battery, and it was amazing. A little overpowered, but definitely awesome. The 2600 KV motors were a bit too fast for that kind of voltage, but it was easy enough to control that with a throttle limit on my Taranis. So at the beginning of 2018, I ordered a full set of 5S packs and enough parts to build a second, nearly identical quad. This time, I used ZMX FinX30 2600 KV motors. These are 2207, while the T-Motors are 2306.

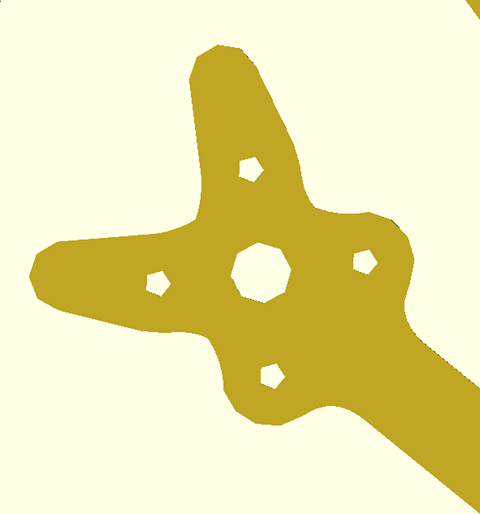

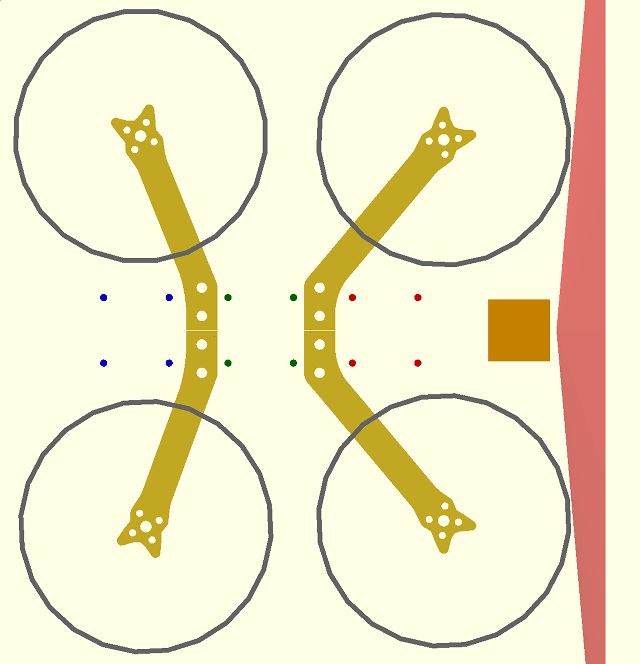

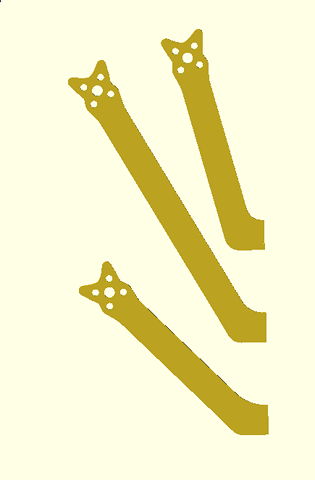

In May, I decided it was time to try a proper freestyle frame with a top-mount battery. I didn’t want to drift too far from my existing pair of quads. I decided to build a quad using the 6” Hyperlite Flowride frame. The arms on the Flowride are a little on the narrow side, so I figured it was time to make the move to a 4-in-1 ESC, so this time, I used a Tekko32 4-in-1.

I absolutely loved the Flowride frame with 5.5” props, so I ordered two more frames. It was a piece of cake migrating the components from my other two quads to the new frames. The arm-mounted ESCs look silly, but I figured when they eventually got smashed, I could upgrade to them to Tekko32 4-in-1 boards, too!

Upgrading to a Helio Spring

I had a weird problem with my Flowride quad. The flight controller, a Kakute F4, would randomly lock up—usually after a snap flip or roll.

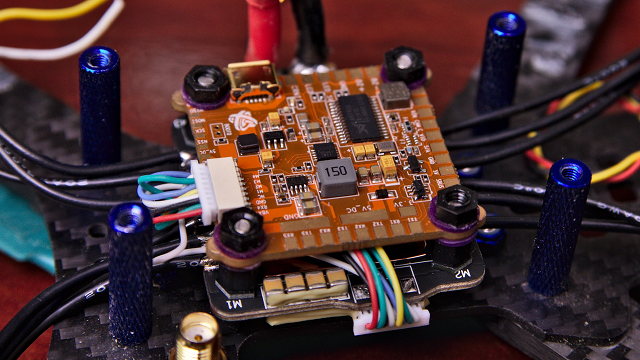

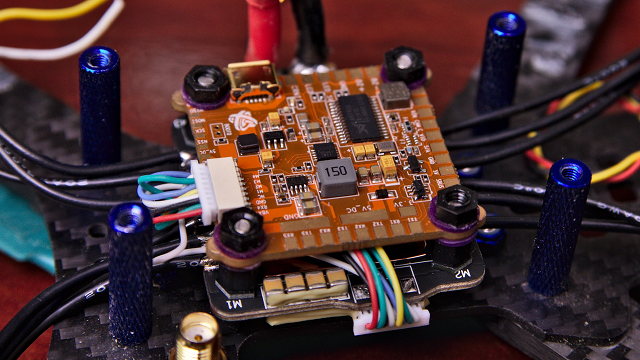

I’d been intrigued by the idea of the Helio Spring flight controller for a while. It runs the gyro filtering separately on an F3 chip, and it runs Betaflight, Butterflight, or Raceflight on an F4 chip. This seemed like a good opportunity to give it Helio Spring a try, so I ordered one.

Not only did the replacement flight controller solve all my problems, but this was the best flying quadcopter I have ever flown. The Helio Spring’s propwash handling was amazing.

Even after transferring the Kakute F4 and other components on my two OwlRC Dragon quads over to identical Hyperlite Flowride frames, I rarely fly them. The quad with the Helio Spring just flies so much better. Every time Betaflight for my standard F4 boards starts to catch up, the IMU-F firmware on the Helio board seems to get an update, and it pulls ahead.

My Helio quad also has less noise in the video feed—the Tekko32 is so much cleaner than the Wraith32 ESCs. I usually only fly the Kakute F4 quads when something bad happens to my Helio Spring quad!

2018 was tough on my quads

I’ve had a lot of small failures on all my quadcopters this year. I’ve broken a few motors. I’ve burned out some ESCs, including two Tekko32 4-in-1 ESCs.

One of my Kakute F4 quads is down to three good ZMX FinX30 quads. The fourth is working, but it isn’t as smooth as it should be.

My Kakute quad with the T-Motor F40 motors has developed a twitch. Is it a bad ESC? Is the gyro going bad? I’m not sure, but it seems like a good excuse to upgrade it to a Tekko32 and a Helio Spring!

The first Tekko32 on my Helio Spring quad failed slowly. One corner started dipping on snap rolls, and that corner’s ESC was weak enough that it was limiting the entire quad to about 70 amps most of the time. Usually it could hit 150!

I lost the second Tekko32 just a few weeks ago in a crash. I smashed a motor, and one of the Tekko32’s 4-in-1’s speed controller modules was scorched in the crash. I’m not sure that a beefier ESC would have helped. When a motor gets stuck like that in a crash, a lot of power can flow easily and very quickly. It seems like that’s the most likely time to fry an ESC.

Choosing motors and getting ready for 6S

I decided to order a fresh set of motors along with my replacement Tekko32 for the Helio Spring quad. Which motors, though?

I prefer the feel of my 2207 motors, so I was looking at T-Motor F60 Pro V2 motors. I fly my 2600 KV motors with an 80% throttle cap. Naive math says a 2100 KV motor on 5S would be comparable to a 2600 KV on 5S—not quite the truth, but it is a close enough estimate for my research purposes. The T-Motor F60 is available in 1750 KV and 2350 KV. That’s either too low for 5S or too high for 6S.

I briefly considered trying the Stingy Edition Rotor Riot Hypetrain motors. They’re 2150 KV 2207 motors. That’s pretty reasonable, and only a little too high for 6S.

Hyperlite LR Edition 2207.5 1922 KV motors

In the end, I went with the Hyperlite LR Edition 1922 KV 2207.5 motors. I’m extremely pleased with my choice. They feel fantastic at 100% throttle with 5.5” props on 5S. They’re a bit lacking on the top end with 5” props on 5S, but they’re not short enough on power that I’m complaining.

1922 KV seems like a good compromise for me. When using my existing 5S packs, that’s comparable to a 2400 KV motor on 4S. In the future, when I upgrade to 6S, it will be comparable to a 2800 KV motor on 6S. This math is rather naive. The real world doesn’t scale quite like this, but the numbers make it easier for me draw comparisons to my older quads.

Since so many of us flew 4S for so long, I am often asking myself, “What would this motor be equivalent to on 4S?” I like to think of this like the old Pentium Rating that Intel and Cyrix used to use.

I now have a nice, smooth, 5S freestyle quad. I borrowed a couple of 1000 mAh 6S pack from my friend Brian. They’re perfect for my quad. They’re 30 or 40 grams lighter than my 1300 mAh 5S packs. According to the GPS, my top speed that day increased from 86 MPH on 5S to 95 MPH on 6S, and I can really feel the difference when punching the quad over trees.

6S is definitely in my future, but I’m content to continue flying my 5S packs until they begin failing.

My backup quad has also gotten the full upgrade

I have seven good F40 motors remaining. I expected to use them on my backup quad, and I expected it would take a long time before I burned through four of them.

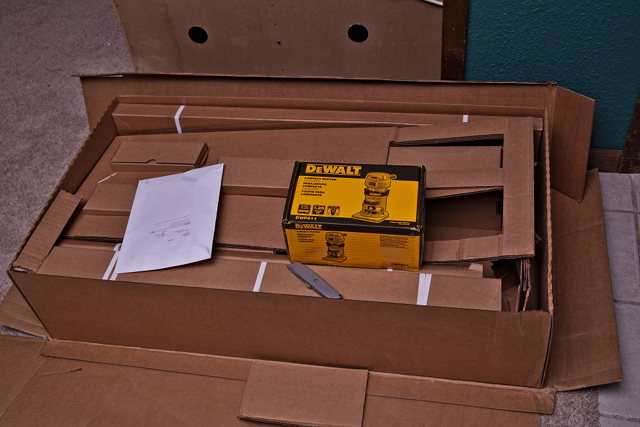

I’ve been enjoying the Hyperlite 1922 KV motors too much. I didn’t just order a Helio Spring and Tekko32 to get my backup quad back into the air. I also ordered another set of Hyperlite 2207.5 motors.

I’m super excited about this. For the first time, I’m have two completely identical quads!

For now, my tertiary quad will still be running parts from my 2018 build. I’ll have plenty of spare motors, ESCs, and flight controllers to keep it flying. This will be the quad I bring out when I do something risky where I’m likely to lose or destroy a quad. I have no excuses now. I need to start posting videos flying over rivers, creeks, and lakes!

The parts list for my current build

Aside from the frame, all of the parts on my 2018 quadcopters were some of the most expensive components you could buy. This year, some of my components are priced a little better.

I shopped for an ESC upgrade, but I thought it was best to stick with the Tekko32—mostly due to laziness! I looked at the Aikon AK32 4-in-1. It looks like it has even more filtering than the Tekko32, and it only costs about $15 more. Connecting the Aikon to the Helio Spring looked like it was going to be too much work. The Tekko32 plugs directly into the Helio Spring—the pin order is identical. The Aikon AK32 has two extra pins. I would have had to make my own cable. I didn’t want to have to do that.

At $21.99, the Hyperlite 2207.5 motors cost $3 less than the F40 or F60 motors from T-Motor. The motors and 4-in-1 ESC don’t add up to a huge cost savings, but it is a surprising savings nonetheless!

I’ve also been saving a few dollars by using the AKK X2 Ultimate VTX instead of the Holybro AtlAtl. When I chose the AtlAtl, it was convenient to have a VTX that mounted in the stack. My frames aren’t tall enough for three boards in the stack, though, so I had to move to something different.

I figured the AKK X2 was worth a try, but I also assumed I was going to be getting what I paid for, and I thought I’d eventually be using something more premium. That wasn’t the case. I’m quite pleased with the AKK, and I’ve ordered two more for each of my other quads.

GPS on a race quad? What!?

I’ve avoided GPS for a long time. I wasn’t opposed to the idea, but support in Betaflight used to be almost worthless, and our older flight controllers didn’t tend to have UARTs to spare. It felt like we were lucky to have just enough UARTs for ESC telemetry and SmartAudio!

Not only that, but the GPS units I remember seeing a few years ago were big, had large antennas, and they cost more than my flight controller. It surely didn’t seem like it was worth the space, expense, and effort to put a nearly useless component on my freestyle quads.

This has changed. Betaflight has a new feature called GPS Rescue, and you can get small GPS modules for $10 to $20. Even with ESC telemetry, TBS Crossfire, SmartAudio, and a GPS module connected, my Helio Spring still has one unused UART. GPS is cheap enough to try and easy enough to fit on my quad now, so why not?

GPS Rescue is absolutely nothing like the return-to-home feature on a DJI drone. If you think you’re going to put this on your freestyle quad to avoid learning to land, you’ll be in for a world of trouble!

GPS Rescue only works if you’ve flown a few hundred feet from your starting location, and it will only return to your general area. It will attempt to land, but I tested that once, and it did a poor job. It doesn’t have a vast array of sensors and cameras available like a Phantom or Mavic, so your Betaflight quad will happily descend into a tree.

This is fine, because it isn’t intended to make your race quad behave like a DJI Spark. It is meant to help bail you out when your video feed gets sketchy.

Sometimes you’re flying at the edge of your video range. You turn around to fly back, and your video gets much worse when your antenna orientation changes. Sometimes you drop behind a hill or you wind up slipping behind a building or wall. These would be occasions when you might be happy to have the GPS Rescue mode switch available to you.

Your quad should climb to a preset altitude and start flying towards you. When your video feed clears up, you can take back over and resume your flight.

It is possible to set GPS Rescue as your failsafe, but this seems like a terrible idea for most of us. Imagine losing your control link while under a tree or while flying inside a building or parking garage. Your failsafe would kick in, GPS Rescue mode would activate, and your quad would immediately ascend into the tree or the ceiling.

The new GPS options have my OSD even more cluttered than ever. Knowing my ground speed is fun, but the other data is mostly useless to me. I have direction to home, distance from home, and number of satellites enabled in my OSD. Once I get GPS Rescue tuned in, I’m hoping I’ll have the confidence to turn half of those options off!

GPS Rescue is worthy of its own blog post.

New props for 2019!

For most of the last year, I’ve flown 5.5” props. I started with the DAL Cyclone T5544C props. They fly great, but they often make it almost impossible to get smooth GoPro footage. A fresh set is usually fine, but one tumble into the grass, and then you’re almost guaranteed to be in Jello City until you change props. They’ll all look fine, but they’re not!

Then I switched to the HQ 5.5x4x3 v1s props. They’re fragile in a different way. They’ll survive gentle crashing without inducing Jello, but when you hit a tree branch, you often completely explode a prop!

I felt it was worth the trouble running 5.5” props. It is a reasonable compromise between 5” and 6” props. 6” props have more bottom-end power that you can really notice when pulling out of a dive. They’re also more efficient, so you’ll usually see longer flight times. The biggest problem with 6” props is their lack of top end. They reach top speed quite quickly, but your top speed tends to be quite limited.

You can say all the same things about 5.5” props. The advantages and disadvantages just aren’t as pronounced. You can catch yourself from a dive with 5.5” props almost as well as with 6”. I was getting flight times that were 20% to 25% longer with 5.5” props compared to 5”. The lack of top speed isn’t as bad with the 5.5”, either.

So why am I giving up the 5.5” props?

I had a lot of luck with getting smooth flight footage using HQ 5.5x4x3 v1s props, but when my stock was running low, they were out of stock everywhere. They haven’t been restocked, either, so I’m assuming they’ve been discontinued. Flying DAL T5544C props is way too frustrating, so I needed to find a plan for the future.

I tried out an old set of Racekraft 5051 props that I found in my closet. Racekraft 5051 props are awful for freestyle—they’re very, very noisy. That doesn’t matter, though. They’re a ton of fun, because they are so damned fast!

With the 5.5” props, I have to limit my throttle to 80% when I fly 5S on 2600 KV motors. Any higher, and the props flatten out, and the quadcopter sounds like a banshee. I usually don’t pull more than 125 amps on 5.5” props.

The Racekraft 5051 props are super stiff. They can go flat out with my high KV motors with too many volts. At 100% throttle, they have no problem breaking 180 amps! They’re stupid fast, even if I use the same 80% throttle cap.

I spent two weeks flying random 5” props that I had in my closet, then I went back to 5.5” props. This was an eye-opening experience.

Going back up to 5.5” props made me realize just how much top speed I was giving up. I was also giving up a lot of responsiveness. Even so, I had quite a collection of 5.5” props, so I waited until I burned through them to order new 5” props.

HQ 5.1” v1s props

I ordered an assortment of 5.1” HQ props. 5.1x4.1x3, 5.1x4.6x3, and 5.1x5.0x3 v1s props. They’re all fantastic.

The 4.1 pitch props feel extremely responsive, and the 5.0 pitch props feel like they offer a lot more punch.

I only have a few sets of each of those two props. I ordered a whole mess of the 5.1x4.6x3 props, and I didn’t even wait until I had a chance to try all three. I figured if I was going to make a mistake, I’d err towards the middle. I’m low on props, so I couldn’t exactly wait until I finished trying all three to order more!

The 4.6 pitch HQ props are a good balance between efficiency and thrust. With my relatively huge 1300 mAh CNHL 5S packs, even a rather high-throttle freestyle flight lasts at least three minutes. I’d say I average a little over 3.5 minutes, and I’ve had some gentle proximity flights approach six minutes.

I don’t know if it is just the props, improvements in Betaflight, or improvements in the recent release of the 1.1.0 IMU-F firmware, but I tend to have Jello-free GoPro footage almost all the time now.

I purposely flew the same set of HQ props several days in a row. Even after some pretty rough crashes, I just bent the props back into shape and kept flying. When one of the props still had a visible crease, I thought for certain that I’d have major shaking in my GoPro footage when I got home. It was still smooth as glass. It was awesome!

I haven’t had that kind of luck with every set of 5.1” HQ props. Sometimes things are unbalanced in just the right way that I do get Jello in my GoPro footage. I had shaky footage eight batteries in a row the other day. The props looked reasonably clean, the quad sounded normal, and it flew great. I just have to be more vigilant.

At any rate, having bent props occasionally causing Jello is a huge win over the DAL T5544C props, because they often caused Jello in the GoPro after touching a few leaves!

4S vs. 5S vs. 6S

I’ve been flying quadcopters with a huge compromise for almost a year now. I built my 2018 quadcopters to be capable of supporting 6S voltage, but I assumed I would be running mostly 4S batteries. So I built my quads with 2600 KV motors. I enjoyed the high KV 2305 motors on my old Holybro Shuriken X1, so I figured the newest revision in the same lineup of motors was a good plan.

Those motors were a ton of fun on 5S, but I can see now that it wasn’t the smoothest setup. Even with the throttle capped at 80%, they still had an explosive amount of power—more power than I needed. The throttle cap doesn’t limit the amount of power Betaflight has available during flips and rolls or when it is attempting to stabilize your craft. This made tuning a bit difficult.

Today, my compromise is in the other direction. I have a stack of 5S batteries, and I know for certain that I will be replacing them with 6S batteries as they start to age and fail.

On 5S with 5.1” HQ props, I would almost tell you that my new quads have all the deficiencies of 5.5” or 6” props with none of the advantages. The top speed is limited quite a bit with this combination of voltage and KV, but I’m also not seeing that instant torque when pulling out of a dive like you do with 5.5” or 6” props.

I also don’t get that explosive acceleration that I was seeing on 5S with the Racekraft 5051 props on 2600 KV motors. That stupidly fast acceleration combined with the high top speed was fun, and I certainly don’t expect to see it on 5S or 6S with 1922 KV motors.

I don’t mean to sound like I’m complaining. This is the best freestyle setup I have ever owned. It is smooth, snappy, and it is usually rather difficult for me to induce propwash oscillations.

When I moved up to 5S, it was a really good value. Reasonable but budget-friendly 4S 1,500 mAh packs cost about $20 to $22 at the time. My 1,300 mAh 5S packs from CNHL were around $25. These 5S batteries are a bit heavier than the $20 1,500 mAh 4S packs, but that just means that they have more capacity. They cost about the same or less than 4S packs if you measure by the watt hour.

At the time, 6S packs weren’t available in as wide a selection as they are today. I would have been paying $35 to $40 per pack. I save a lot of money, and the efficiency and power gains when upgrading from 5S to 6S aren’t that dramatic.

6S batteries really open this quad up. I ran two of my friend Brian’s 1,000 mAh CNHL 6S packs. They’re 30 or 40 grams lighter than my 1,300 mAh 5S packs, which is nice, and they make the quad go quite a bit faster.

There are two reasons why I’m upgrading to 6S, and Brian’s batteries are one of them. The most commonly available 5S battery for miniquads is 1,300 mAh, and they weigh nearly 220 grams. That’s too heavy. If there were a reasonably priced 5S pack somewhere around 180 grams, I wouldn’t have chosen 1922 KV motors. I would have shopped from something in the 2200 to 2300 KV range and kept on flying 5S.

Brian’s 6S 1,000 mAh packs from CNHL weigh about 185 grams, and they cost about $28 each. I’m excited about this weight savings. I’ve only flown two of these packs so far, but my quad felt so fast and nimble, and my flight times were comparable enough to my 1,300 mAh 5S packs. I’d hate to make a judgment about that without more data, but I think I’m going to be pleased with my future battery upgrade.

The future of this build

As long as I’m talking about the future, I may as well talk about cameras. My GoPro Session 5 hasn’t failed yet, but I’m worried about it. The back cover isn’t attached correctly anymore, and I suspect there will be a camera upgrade in my future.

I’m bummed out that the Session 5 has been discontinued. It is a fantastic form factor for FPV freestyle quads, and it is quite a bit more durable than the larger GoPro cameras—especially when it is inside a nice TPU mount. There’s still a small chance that I’ll buy another Session 5, but their price at Amazon is already approaching the same price as a GoPro Hero 6 Black.

I’m excited about upgrading to a full-size GoPro. Even the Hero 6 Black would be a big upgrade. The Session 5 has a minimum ISO of 400, while the Hero 6 Black can go down to 100. That would make ND filters slightly less necessary. Not to mention the video quality is just a little better overall.

The full-size GoPro cameras weigh roughly 45 grams more than the Session 5. I’m not excited about the idea of flying a freestyle quad that weighs more than 700 grams. My current weight with the Session 5 and a 1,300 mAh 5S pack is just shy of 680 grams.

I’m hopeful that I’ll be shedding enough weight in the future to even things up. When I upgrade to 1,000 mAh 6S packs, I’ll be losing 30 grams.

Plugging a heavy TBS Triumph antenna into an MMCX to SMA adapter is wasteful. I could probably save another 10 grams or more by plugging a Lumenier AXII antenna directly into the VTX. Unfortunately, there’s not a lot of room in the back of my Flowride frame for a VTX, so I have it sitting between the camera and the flight controller. I’m not so sure that saving 10 grams is worth the effort, but we’ll see.

I won’t be surprised if half the batteries I carry will be 6S within the next 3 months. I currently carry eight 5S 1,300 mAh packs, and I bring along a field charging setup if I’m going to spend more than 20 or 30 minutes in the air.

Three of my 5S packs are getting pretty old and tired. Old enough that I’ve started thinking of them as my warm-up packs. It won’t be long before they need to be retired, and when they are retired, they’ll also need to be replaced!

Conclusion

I honestly didn’t think I’d have all that much to say about this upgrade. I switched frames nearly six months ago, and the only significant change I’ve made to the hardware since then is the motors. Yet here I am about to break 4,000 words on this post. How did this happen?!

Most of the components in this build have served me well for six to twelve months so far, and I expect that all the hardware in this build will be durable.

What do you think? How did I do? I feel like I chose the perfect motor for my transition for 5S to 6S. Do you think I should have chosen any different components this time around? Let me know what you think, or stop by our Discord server and chat with me about it!