I am a huge fan of mechanical keyboards. I type thousands of words every day. I write blog posts. I write emails. I’m constantly sending instant messages or chatting in Discord.

If you use a piece of hardware several hours each day, you should definitely invest in good hardware. If you sit at your desk for eight hours every day, invest in a good desk, and buy yourself a nice chair like an Aeron. Your back will thank you, and your Aeron chair will still be in near mint condition in ten years!

- It’s Great to Be Using a Mechanical Keyboard Again at patshead.com

- You Might Need A Macro Pad: The JC Pro Macro 2 Mechanical Keypad at patshead.com

Expensive mechanical keyboards

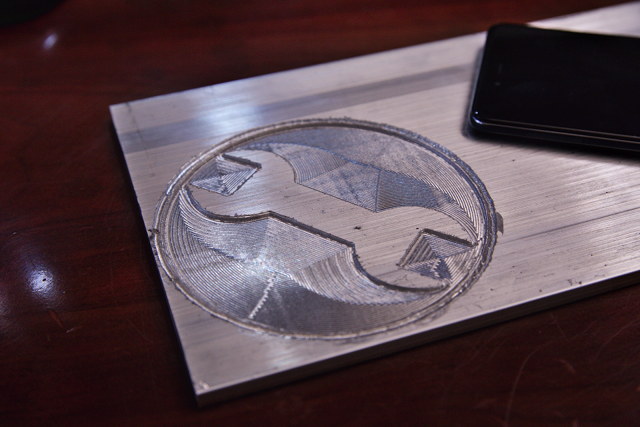

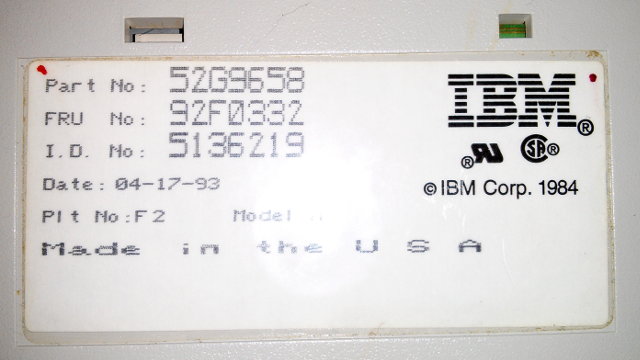

My favorite mechanical keyboard is the venerable IBM Model M keyboard. As far as I’m concerned, there’s just no substitute for buckling-spring keys. My current Model M keyboard is stamped with a manufacture date of April 17, 1993. It was used in an office for roughly six years. I even know exactly which office!

These used to be cheap. In the late nineties, I remember ordering ten of the rare Model M keyboards that lacked number pads. It was about $100 shipped for the lot, and they were all in perfect shape. Today, those same keyboards are listed on eBay at prices ranging from $250 to $450 each!

If we can trust my blog, I used that keyboard for about five years starting in 2013. About two years ago, an old friend sent me a Razor BlackWidow keyboard with Cherry MX Green switches. I’ve been using it ever since.

The green switches aren’t bad. Whenever people ask me how they feel, I always wind up saying they feel crunchier than the Model M’s bucking springs. I often think about switching back. In fact, I’m thinking about it right now. Writing about keyboards makes me ponder this stuff!

Similar Razor keyboards are around $100 or so. Used IBM Model M keyboards are vary in price, but they can be had for $100 or less on eBay.

- It’s Great to Be Using a Mechanical Keyboard Again at patshead.com

- You Might Need A Macro Pad: The JC Pro Macro 2 Mechanical Keypad at patshead.com

- 2019 Razor BlackWidow at Amazon (newer model than mine!)

What about cheap keyboards?

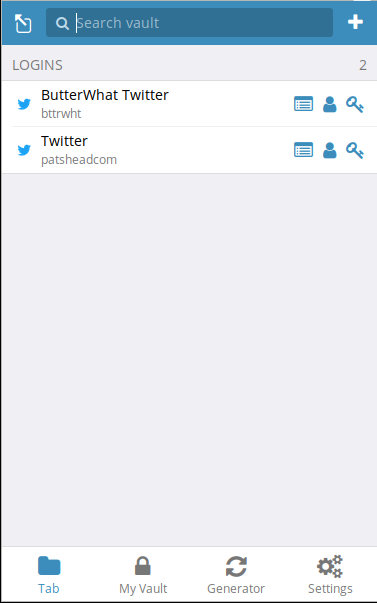

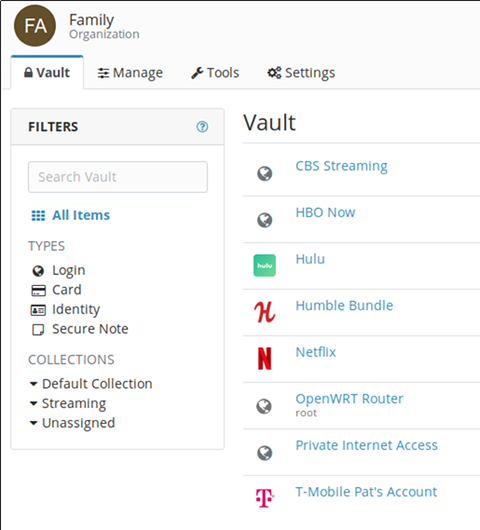

I recently posted a couple of keyboard deals on Butter, What?!. Both keyboards use a clone of the Cherry MX switch made by a company called OUTEMU. I don’t like to recommend products I don’t use myself, but both keyboards were priced under $30. It seemed like a great way for someone to decide if they like mechanical keyboards, so I thought it was worth telling everyone about the deal.

This is @Libbets's $28 mechanical keyboard that I posted to @bttrwht three weeks ago. It has all sorts of magic RGB settings. This is the one she seems to have decided she enjoys! pic.twitter.com/enKjlD5Jst

— Pat Regan (@patsheadcom) July 18, 2019

I ordered the DRECO Durendal keyboard with OUTEMU MX Red switches for my wife. That means I have had an opportunity to test it out.

I prefer the more tactile switches like the Cherry MX Blue or Green, but other than that, her cheap keyboard feels fantastic. It has some heft to it, the keys feel fine, it has N-Key rollover, and it has all sorts of preprogrammed RGB LED modes. My only complaint about her keyboard would be that the wrist rest is molded into the keyboard, and it cannot be removed.

I use a cheap mouse!

I tell everyone they should invest in the gear they use the most. I use my mouse every day, but I use a cheap mouse. This seems a little hypocritical to me, especially when you consider that I manage to spend several hours on at least three or four nights each week playing Team Fortress 2!

It is an E-Blue Mazer wireless gaming mouse. They’ve been using one since 2015, and they’re priced at around $20 with free 2-day Prime shipping at Amazon.

It works just fine. Mice aren’t exactly rocket science. There are microswitches in the buttons, an optical encoder on the wheel, and a camera of some sort underneath. When you upgrade to a better mouse, you aren’t getting entirely different technology like you are with a mechanical keyboard.

These wireless mice are cheap enough that we keep one in every laptop bag, and there’s one on each our desks. I’m on my second E-Blue Mazer mouse. One of the Teflon pads started to come off my first mouse. I have extra Teflon skates in a drawer, but I didn’t bother sticking any on. Why bother? A new mouse is $20!

It works great. It is a bit lower profile than most mice, but that stopped bothering me after two days. It is comfortable, and the battery lasts for months. I don’t turn on the gaudy blue lights, though.

- The E-Blue Mazer II Wireless Gaming Mouse at patshead.com

- E-Blue Mazer II 2500 DPI Wireless Gaming Mouse at Amazon

I tentatively support cheap mechanical keyboards!

I don’t see any reason to be down on cheap mechanical keyboards. Just like with mice, the cloned Cherry switches are now just a commodity. The expensive mouse might have higher quality microswitches, and I’m certain that Cherry has better quality control than OUTEMU. They feel similar.

Will the cheap keyboard last as long as a Razor BlackWidow? Probably not. Will my Razor BlackWidow last as long as my IBM Model M from 1993? Probably not. Will they last long enough? Most likely!

Mechanical keyboards are like underwear. You need to choose your own style. Some people prefer boxers. Others are more comfortable in tighty whities.

I like the heavy, solid Cherry MX Green switches. Maybe you won’t. Maybe you’ll prefer one of the softer keys, or the linear keys. Who knows?

You’re going to have to try more than one switch. You can buy small boards with five or six different keys attached. I don’t think this is a good way to really get a feel for what it is like to type with these switches, though. You’re going to have to try more than one keyboard.

Maybe your friends have keyboards you can try. Maybe you can stop by Micro Center and feel up some of their keyboards. Maybe you can just start buying cheap keyboards just to see what you like. They can get so inexpensive these days that they don’t cost much more than membrane keyboards!

Conclusion

Chris has only had her inexpensive mechanical keyboard for a week or so. We’ll see how it holds up. I’ll be surprised if she breaks a key. In my experience, keyboards tend to be pretty durable. Even the cheap, garbage keyboards I’ve bought in the past have held up well. Wired electronics are pretty simple, eh?

What do you think? Do you have a keyboard with off-brand Cherry MX clone switches? Should I keep posting inexpensive mechanical keyboard deals on Butter, What?! There’s no way I can test every keyboard, but I still think I should keep you apprised of these deals anyway. Let me know about it in the comments, or stop by the Butter, What?! Discord server to chat with me about it!

- You Might Need A Macro Pad: The JC Pro Macro 2 Mechanical Keypad at patshead.com

- It’s Great to Be Using a Mechanical Keyboard Again at patshead.com

- Deal: Budget Mechanical Gaming Keyboard with Brown or Red Switches (Expired) at Butter, What?!