I’ve had an idea stewing around in my head for years. It started when I saw a Dekatron posted on hackaday.com. Dekatrons are high-voltage vacuum tubes, but they seem easy enough to emulate with LEDs. There are all sorts of things I could indicate using a ring of LEDs!

You could use it like a clock. You could use it as a progress bar. You can spin it around at various speeds. A Dekatron seems like a lot of fun!

At the time, I wanted to replace the lock indicator LEDs on my IBM Model M keyboard with three tiny Dekatrons. I never did, but I also never stopped thinking about what I would do with a ring of spinning LEDs.

We’re going a bit bigger

Brian has been building and giving away custom DIY NAS servers for years. We were chatting about it one day, and we were thinking that we need something of our own to use in those builds. Then we completely forgot about it for a few months.

Then I remembered my obsession with Dekatrons. Why not design some LED rings to put into a 5.25” drive bay in your server? The LEDs could spin to indicate network traffic. They could light up like a progress bar to indicate disk utilization. They could flash red lights to indicate a drive failure!

NOTE: I didn’t even remember seeing real Dekatrons mounted in a 5.25” drive bay on Hackaday until I was attempting to find that old article that inspired me many years ago. I don’t know for certain that this is the project from my memory, but I’m betting that it is. It looks like I’ve circled all the way back to the beginning!

I don’t know how to design a PCB. Brian doesn’t know how to design a PCB. So what do we do? I happened to talk to a friend that’s been dabbling in this sort of thing as a hobby.

In the end, we thought up something pretty cool!

- DIY NAS: 2019 Edition at briancmoses.com

OoberLights

We decided to use WS2812 RGB LEDs in the ring. This opens up all kinds of neat possibilities. The disk-utilization progress bar can be blue. The spinner for incoming network traffic could be red and spin clockwise. The spinner for the outgoing network traffic might be green and spin counterclockwise. Maybe the spinner could be a bright, white LED with a red and orange trail following it!

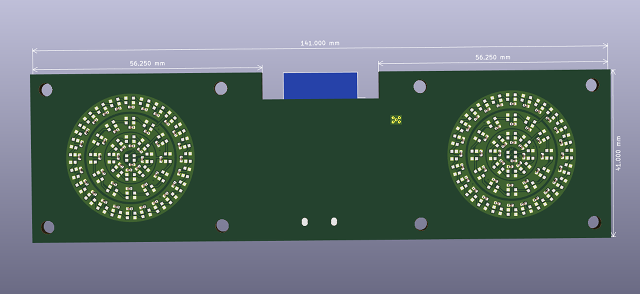

My vision only included fitting a pair of simple LED rings side by side, but my friend is more ambitious than me. He decided to include concentric rings of LEDs! Both discs of LEDs is now three concentric rings, with fewer LEDs in each ring as you approach the center. He also included a single LED at the center.

This is awesome, but it has made my job more complicated. I was ready to display some useful data about your server on a pair of simple rings. To utilize all these extra lights, I am going to have to get creative!

We’re no longer limited to spinning. The OoberLights can pulse in and out. They can also be used to crudely simulate the hands of a clock. I’m even wondering if they’re dense enough to display a simple font. This is going to be so much fun!

OoberLights can sit on your desk or on a shelf!

Some people put their computers on display prominently on their desks. I’m an old man. I’m used to my computer being a plain beige box, and I don’t want it cluttering up my workspace, so I hide it on the floor. I don’t want my OoberLights hiding somewhere behind my desk or on the floor!

We’re going to design a small display case as well, so you can place your OoberLights right in front of your monitor or up on a bookshelf.

How is it going to display anything useful if it isn’t connected to my computer?!

I thought it was important for the OoberLights to have WiFi connectivity, so we’re using an ESP8266 microcontroller. We are going to allow you to control the lights via WiFi using an HTTP REST interface or directly over the USB port. The USB port will also be used for power.

How do you control the OoberLights?

My expectation is that the software will get fancier over time, but I have some plans for how we’re going to get started.

I don’t want you to have to know how to write complicated code to get the OoberLights to do something interesting. I want them to be able to do fancy things right out of the box.

We’re planning on having simple text commands to control things like progress bars, spinners, and other things. I want various bars and spinners to be able to be active at the same time. You’ll be able to give it commands along the lines of, “display a blue spinner at 60 RPM,” or “give me a green, clockwise progress bar from 0% to 33%,” and the device will render these for you.

If you’re a UNIX junkie like me, this will make it easy to string a handful of commands together and pipe the correct command over the USB serial port to the OoberLights to display exactly what I want.

I expect that one of our first projects will be designing some sort of open-source agent to run on Brian’s FreeNAS boxes to push useful information to some OoberLights.

Everything will be open source!

I haven’t talked about which license we will be using, but the hardware and software will definitely all be open source. We don’t even have our first prototype built yet, though, so this may take a little while. We have no idea what we’re doing!

The first prototype is close!

I’ve gotten a few recommendations on local shops than can manufacture our prototype OoberLight PCBs for us. I thought about ordering PCBs and all the surface mount components and soldering them onto the boards myself. I know I could manage to solder a few components on, but there’s 90 LEDs on each board, and nearly as many other individual components as well! This is beyond my skill level.

We’ve never designed anything this complicated before. I’m having an experienced friend check it over, but even so, what are the odds that the first prototypes will even be functional? We don’t know! It’ll be fun to find out!

What’s the timeline for a release?

Who knows! I’ll be excited if we can be manufacturing real OoberLights in time for Brian’s next DIY NAS giveaway. It sounds like his next EconoNAS giveaway may be less than six months away. Do you think we can do it in time?

What needs to be ready by then?

The hardware needs to be finalized, of course. The possibilities for animations and things that the OoberLights can do seem nearly limitless. We can’t implement everything in version 1.0 of the firmware. We’ve thought of a lot of ideas already, and I have a feeling those ideas are only the tip of the iceberg.

We need easy firmware updates. It looks like it won’t be difficult to allow firmware updates over HTTP. We’ll see how that goes in practice. If we have to plug in for firmware updates, I won’t be too disappointed, though.

To be ready to ship, the OoberLights need to be controllable over both WiFi and USB, and they need to be able to display multiple spinning indicators and progress bars simultaneously. I think that will be a pretty awesome start to the project!

How much will the OoberLights cost?

This is a very good question. I wish I had a good answer!

We have a rough idea of what the components cost. I have some guesses as to what the prototypes will cost—they won’t exactly be cheap!

I don’t know what quantities we’ll be ordering yet, so I don’t know what sort of volume discounts we’ll be able to get. The more people that are interested, the better the pricing will be!

What do you think?

Do you want crazy, spinning blinkenlights on your desk or in your PC case? I sure do! I want one in my virtual machine server. I want one in my workstation. I want one on my desk keeping count of retweets and visitors to my blog!

If you think this is interesting, let me know! Leave a comment. Tell me about what I’m forgetting. Tell me if you want one. Stop by the Butter, What?! Discord server to tell me about it. The more interest we see, the more we can order, and the better the pricing will be for us and for you!

- Drive bay form factor dual Dekatron readouts for RAM and CPU usage at Hackaday.com

- DIY NAS: 2019 Edition at briancmoses.com